This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

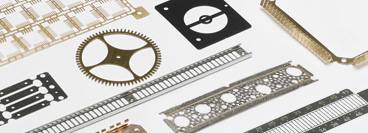

Metal Etching

The Fotofab process features a trio of fundamental improvements over other manufacturers, including reduced costs, faster speeds, and higher precision parts.

We also source materials and manufacture completely within the United States.

Benefits of Photochemical Machining

(Chemical Etching)

Faster Production

Photochemical machining (chemical etching) typically takes less than a day, often less than an hour, to complete. This means your custom, brand new parts are ready to ship the same day.

Standard lead times are between 5-7 days from the order date, with an optional expedited service available.

Inexpensive Photools

Pricing for the majority of phototools used in photochemical selective etching is thousands of dollars less than the cost of using hard tools for stamping equivalent metal parts.

Higher Precision

Fotofab uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

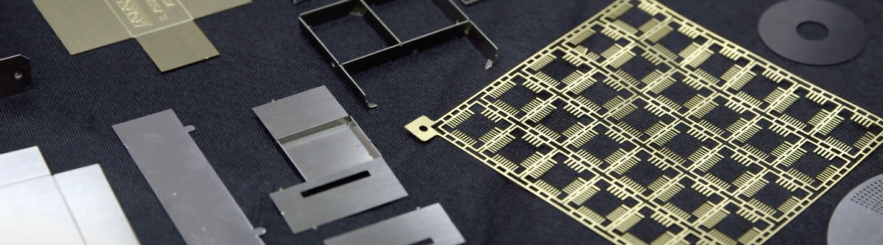

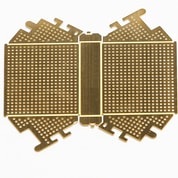

- Photochemical Machining or Chemical Etching has the ability to produce complex geometries within very strict tolerances, and the good news is that increased part complexity is very rarely a cost driver.

- Production Volume – We have the capabilities to help with your prototype and high-volume production orders.

The Photo Etching Advantage

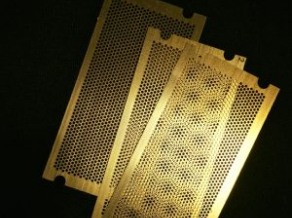

Photochemical etching produces precision metal parts more precisely and with tighter tolerances than metal stamping, laser cutting, CNC machining, and wire EDM.

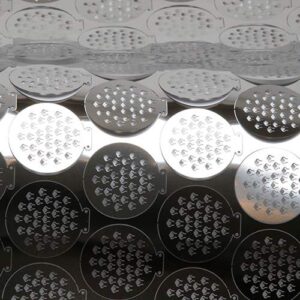

Chemical etching (photo etching) is a photo-lithographic process whereby a phototool is used to block UV light from exposing the area of a sheet of metal that has first been cleaned and laminated with photoresist. The sheet is then developed to wash away the unexposed photoresist leaving a very precise mask of hardened photoresist behind. This patterned sheet is fed through concentrated etchants which dissolve the exposed material leaving exact-to-print parts.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals, including:

| Metal Name | Description | Available Alloys | |

| Aluminum | Aluminum is a lightweight, highly conductive, reflective, and non-toxic metal. Its durability and corrosion-resistant properties make Aluminum chemical etching ideal for components in a variety of industries. | 1100, 2024, 3003, 5052, 6061 |

| Beryllium Copper | Beryllium Copper (BeCu) is a pliable metal alloy with high electrical conductivity. Beryllium Copper chemical etching is ideal for applications in electrical and electronic industries, such as contact and spring contact applications. | |

| Brass | Brass is a binary alloy composed of Copper and Zinc. It is similar to Bronze and valued for its workability, hardness, corrosion resistance, and attractive appearance. | |

| Copper | Copper chemical etching is an excellent process for applications in the electrical and electronic industries. This soft metal possesses high thermal and electrical conductivity and is one of the easier metals to photo-chemically machine or etch. | C11000, C10100, C26000, C51000, C52100, C71500, C77000 |