This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

When to Select Photochemical Machining (PCM) over the Others

There are a lot of ways to form and shape metal. Photochemical etching (PCM) is one way to create thin, precision metal parts for aerospace, defense, and medical applications that require tight tolerances.

The process uses a chemical solution to etch away metal and create intricate designs and complex geometries without inducing stress.

Other traditional metal manufacturing methods include:

- Laser Beam Machining

- Photochemical Electro Forming (PEF)

- Stamping

- Water Jet Cutting

- Wire Electrodischarge Machining (Wire EDM)

To determine if PCM is the right process for your application, here are a few details about its rivals.

Fotofab products are made in the USA and distributed worldwide.

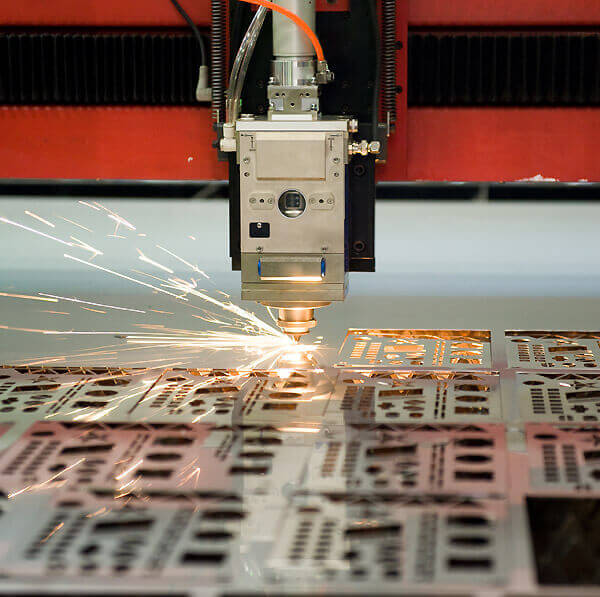

Laser Beam Machining (LBM)

Laser beam machining (LBM), or laser cutting, uses thermal energy to remove material from a surface. LBM rivals PCM in cost effectiveness for medium-batch size production. The more complex a part, the more economics favor chemical etching.

In comparison to other cutting methods, laser cutting is easier to automate for complex patterns. Other advantages include:

- Low maintenance costs due to low wear and tear rates

- High precision with no additional finishing required

- Fast cutting rates that can cut at shallow angles

One downfall of laser cutting is that each aperture or edge is machined individually, so complex parts increase machining times and costs, whereas PCM can machine all apertures simultaneously. Laser cutting also introduces heat to the metal, altering its chemical properties and/or integrity and introducing thermal stress on the cutting edge.

Other disadvantages of laser cutting include:

- High power consumption

- Risks of burning or discoloring the metal due to mishandling of the laser beam

- Inability to cut through thick metals

- Potential injury or severe burns if there is contact with human workers

- Inconsistent production and cutting times dependent on the metal or material being cut

Photo Electro Forming (PEF)

Photo electro forming (PEF) applies the photochemical technology but electronically deposits a metal layer on an area not covered by protective films (photoresist), rather than using corrosive liquids to dissolve the surface chemically as in PCM. Electric currents precipitate the metal out of the solution onto a conductive pattern or mandrel.

In comparison to PCM, PEF enables ultra-fine processing at a higher precision. In comparison to other processes, it is less expensive, resistant to processing strains, and highly accurate for metals like:

- Copper

- Gold

- Nickel-Iron Alloys

- Specialized Nickel Cobalt

- Palladium

- Platinum

- Rhodium

- Silver

The PEF process is not suitable for mass production due to its long electrolysis time. Plate development also takes days to complete. While it is effective for extreme tolerances and complexities, the electrodeposited layer must have at least 4 µm or it will crack when it is separated from the base material.

Stamping

Stamping (or pressing) involves placing a flat sheet of metal into a press machine that has a tool and die surface which forms the metal into a desired shape for a variety of industries and applications involving three-dimensional designs or other surface engraving features. There are a variety of stamping techniques including:

- Punching

- Blanking

- Bending

- Coining

- Embossing

- Flanging

The process is fast and cost-effective for large quantities of complex parts. Other advantages include:

- Lower die costs – Metal stamping dies are relatively less expensive to produce and maintain than those used in other processes like CNC machining.

- Lower secondary costs – Cleaning and plating tend to be cheaper than similar treatments for other metal fabrication processes.

- High level of automation – Stamping machines can be automated with high-end computer-control programs, providing greater precision, faster production, and quicker turnaround times with lower labor costs.

While the tools used for stamping are effective for miniaturization, they can be quite expensive along with the costs of the presses. The dies must be acquired or created which lengthens the time of pre-production (6 to 8 weeks), and they can be difficult to change if the design must be altered during production. They are not as accurate as PCM and are prone to processing strains or burrs on the material, especially with very soft, hard, or brittle materials.

In comparison, photochemical etching is more precise, less time-consuming, and more affordable. Photo-etching tooling can be created in a matter of hours and changed just as fast for prototyping purposes enabling 48-hour lead times compared to weeks typical of stamping.

Water Jet Cutting

Water jet cutting involves a high-pressure jet of water (or a mixture of water and an abrasive substance) to cut through a variety of materials for industries like aerospace and mining. The process works well on metals where high temperatures can affect their properties. Other advantages include:

- Clean, highly accurate and precise cuts, specifically internal cuts

- Superior edge quality

- No required tool changes

- No heat affected zones on the material

- Increased cutting flexibility

However, operation costs are high compared to chemical etching, which is more affordable when it comes to prototyping, small volume, or low volume production.

Wire Electrical Discharge Machining (WEDM)

Rapidly recurring electrical discharges, or sparks, are used in Wire Electrical Discharge Machining (WEDM)

to fabricate shapes into metal. The process is primarily used for hard, conductive metals such as Hastalloy, titanium, Kovar, and Inconel that are difficult to machine with other techniques. It is also very effective for small parts with intricate features.

Wire EDM is as cost-effective as photochemical etching for small volumes or producing prototypes; however, etching is more cost-efficient for large-scale, industrial production.

While Wire EDM has a high degree of accuracy, it does have a slow rate of material removal and additional time and costs for creating electrodes for Ram/Sink EDM. Other disadvantages include:

- Deformation, tempering, and structural changes may occur in the metal

- Brass-deposit can be found on the part post-machining

- The tighter the tolerance, the more cuts required to hold

- Each pass results in additional processing time, leading to more costs and longer lead times

- Reproducing sharp corners on the workpiece is difficult due to the electrode wear

- Can form an oxide layer on the material that may require a secondary cleaning process, which can lead to more costs

Photochemical Machining Is The Answer

The process of PCM answers the demand for low-cost, burr-free parts including hardened metals, without inducing stress. It reliably produces intricate, close tolerance patterns in a variety of flat, metal materials. It eliminates the heat transfer issue of laser cutting and the physical impact force of mechanical techniques such as stamping. Intricate parts that are impractical to blank mechanically because of hardness or brittleness of the work material can often be made with ease by photochemical etching. To learn more about our PCM process here at Fotofab, check out our Photochemical Etching Whitepaper.