This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

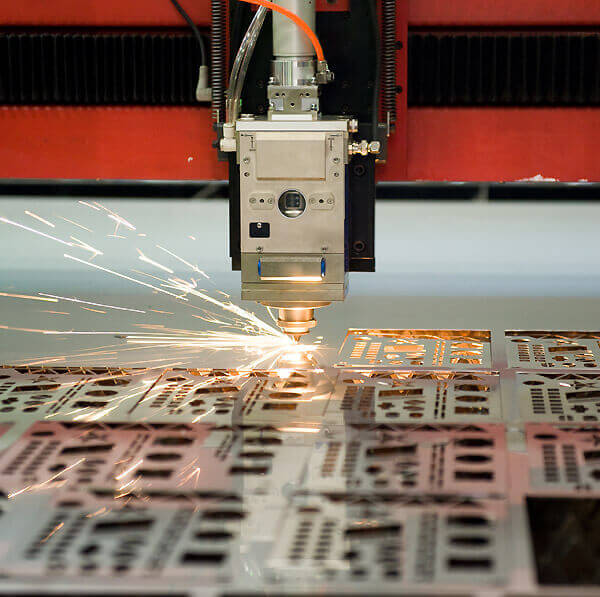

Laser Cutting

Fotofab offers premium laser cutting services for flat metal parts. At times parts are too thick for the photoetching process or the end-use application doesn’t require the extreme precision of photo etching. In these cases, we utilize our extensive network of high-quality vendors to produce and complete your part.

Laser cutting and marking services are available on etched parts produced by Fotofab. Some common requests include:

- Logos

- Barcodes

- Serial Numbers

- Part Numbers

Laser Cutting vs. Photochemical Etching

| Process | Burrs | Stress | Metal Variety | Hardness | Tolerances | % of Metal Thickness |

| Laser Cutting | Microburring | Thermal Stress on Edges | Large Variety | No Problems with Hardness | ± 5% |

| Photochemical Etching | No Burrs | No Stress or Structural Changes | Large Variety | No Problems with Hardness | ± 10% |

Laser Micro Milling

Laser micro milling is a process whereby cavities and pockets can be created on the surface of a piece of material by laser ablation. Its main benefits over photo-etching are that laser micromachining can achieve very smooth surfaces whereas photo etching can only reveal the grain pattern that is rolled into the stock.

Laser micro milling is also used to put the finishing touches on very fine through slots, slots that cannot be made accurate enough by any other method.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More