This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

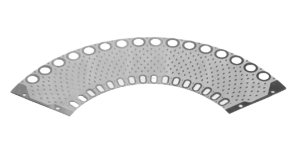

Etched Semiconductor Components

A semiconductor is any class of crystalline solids intermediate in electrical conductivity between a conductor and insulator found in a variety of electronic devices including diodes, transistors, and integrated circuits. Their compactness, reliability, power efficiency, and low cost make them desirable for a wide range of applications in aerospace, defense, medical, telecommunications, and more.

Photochemical Etched Semiconductor Components

Fotofab has over 50 years of experience manufacturing high-quality, thin metal parts for semiconductor applications. Our photochemical etching process produces superior burr- and stress-free semiconductor components with as little as one week turnaround times at lower costs compared to traditional machining processes. We are highly referred by our customers for our responsiveness to their needs for product quality, quick response times, and great customer service.

Typical Semiconductor Applications

Semiconductors are at the heart of the latest electronics trends. They are essential for many electronic systems serving communications, signal processing, computing, and control applications including:

- Portable power devices

- Optical sensors

- Light emitters such as solid-state lasers

- Microprocessors and microelectronic circuits for cars, planes, and space exploration vehicles

- Solar cells

- LED displays

- Radar technology

- Fiber-optic communication devices

- Photoelectric cells found in automatic doors, burglar alarms, and bar-code readers

Metals for Semiconductor Components

There are a variety of materials used to manufacture photochemical etching for semiconductor components including:

- Silver

- Copper

- Stainless Steel

- Gold

Fotofab is committed to quality.

Fotofab Advantages

Fotofab provides a wide range of high-precision metal fabricating services to produce components with simple to very complex geometries. While our core competency has not changed over time, the technology of our production tools continues to evolve. We continue to seek opportunities for our customers to benefit from our unrivaled experience while producing parts with state-of-the-art production methodologies and uncompromising quality standards.