This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

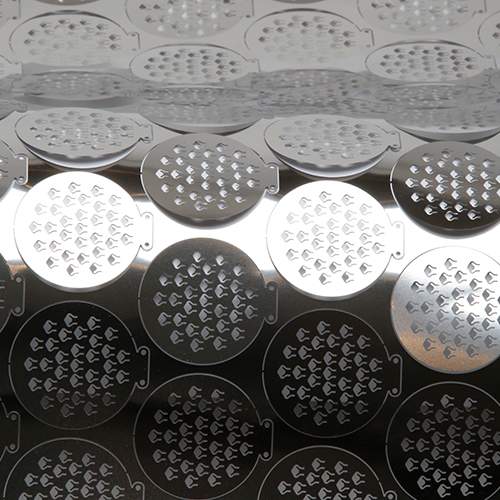

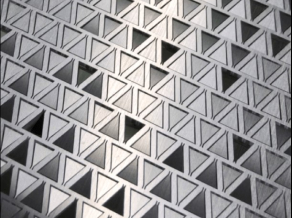

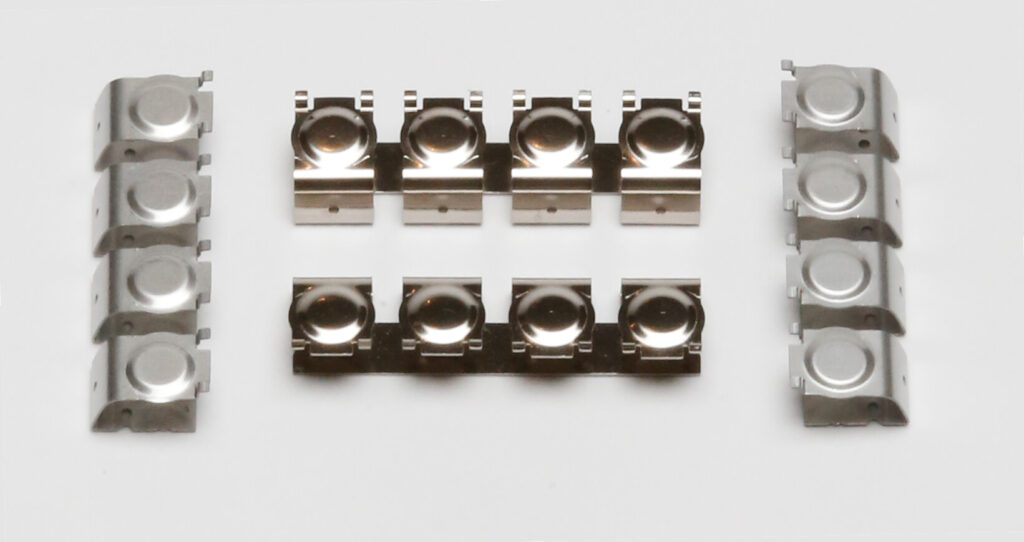

Metal Finishing Services

Fotofab offers a wide variety of value-added metal finishing services to provide you with exact-to-print parts that are ready to use.

Metal Finishing Services

Some of the most commonly requested finishing services we provide include:

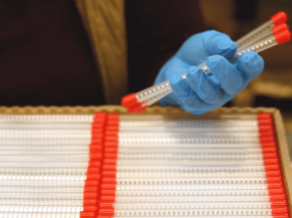

We also offer a variety of custom packaging, from bulk-packed sheets to detached and individually packaged.

Available Metals

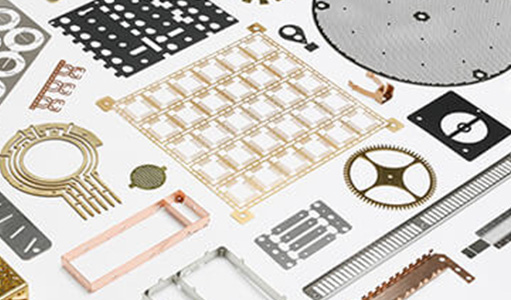

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.

Frequently Asked

Questions

Here are some frequent FAQs about our photochemical etching process and value-added services. Can’t find your question? Feel free to contact us today and we’ll get you in touch with a Fotofab representative!

Is Fotofab ITAR registered?

Is Fotofab ISO/AS9100 certified?

Yes! Fotofab is ISO 9000:2015 and AS9100D certified. The AS9100 certificate includes the requirements of ISO 9001, the DOD, NASA, and FAA system assessments. See our Certifications page for the most recent version.

Can I get a sample?

Yes, please take a moment to fill out the Contact Us form and we will send you some unique samples for your review.

Do you have manufacturer’s reps in my area?

Fotofab has multiple manufacturing reps throughout the United States. Contact Us to locate the representative in your area.

Do you offer plant tours?

Yes. The Fotofab team would welcome the opportunity to show you our manufacturing facilities. Please contact us at 1-773-463-6211 to set up an appointment.

Can you help me select a metal for my application?

Yes, we would be happy to help. Our engineering sales team (or estimators) is skilled at assessing materials and designs for a variety of projects. Please Contact Us for assistance.

Do you work with non-metals?

At this time, we only etch on flat metal sheets.

What metals do you work with?

We etch both standard and exotic metals, non-corrosive, biocompatible, and many other types of metals. For a full list of metals we can etch, visit our Metals we Etch Page

What finishes are RoHS compliant?

Tin plating (dull or bright), black oxide, and black nickel are RoHS compliant finishes. Most other “blackening” finishes and tin-lead plating are not compliant. Feel free to call us with any concerns about RoHS.

What are some advantages of using the chemical etching process?

Low-cost tooling, quick turnaround time, and flexibility in part design.

What are the design considerations when photo etching?

There are some basic minimum hole/slot sizes, minimum inside radii, and other material considerations outlined in our “Design Guide to Photochemical Machining”.

Does photo etching alter the properties of the metal?

No. Unlike traditional machining (such as stamping or laser cutting) there is not stress or extreme heat applied to the metal which could potentially affect the metal properties.

What are the chemicals used in photoetching?

Various chemicals are used depending on the material that is being etched. Common etchants include ferric chloride and hydrofluoric solutions.

Do you accept credit cards?

Yes, we accept Visa, MasterCard, AMEX, and government credit cards.

What type of drawing files do you accept?

STEP, DXF, DWG, and X_T are the preferred formats for drawings.

Who should I contact to send in my RFQ?

Answer…Here are a few ways to send in your RFQ:

Submit Online:

E-mail to sales@fotofab.com

Fax to (773) 463-3387

What is your minimum order quantity?

Our minimum order quantity is two sheets of material. The cost of our minimum lot run may depend on the metal type, thickness, secondaries (plating, forming, electro-polishing, etc) or packaging options.

What are the tolerances associated with etching?

Typically, tolerances follow a +/- 10% of the metal thickness rule. The depth of etch tolerance can be as low as +/- 0.0005″ (0.0127mm).

What is the largest sheet size that you can etch?

As a general rule, 24” (60.96 cm) by 36” (91.44cm) is the overall size. If your application exceeds our guidelines, please contact us with your request.

What is the min/max thickness that you can etch?

We work with metals ranging from 0.0002″(0.005mm) to 0.062″ (1.57mm) in a large variety of metals.

What is your minimum hole or slot size?

The smallest hole diameter or slot width that can be produced by the Fotofab process, as a general rule, is 1.2 times the metal thickness. The minimum practical diameter or slot width that can be machined is 90% of the metal thickness.