This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

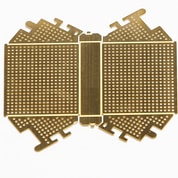

Chemical Etching Brass

At Fotofab, we specialize in the precision chemical etching of brass, crafting components that meet your exact specifications. Our advanced photochemical etching process allows for exceptional detail and accuracy, ideal for both delicate and robust applications.

With capabilities ranging from ultra-fine to more substantial brass thicknesses, we deliver components with superior surface finishes and dimensional consistency. Known for our rapid turnaround and engineering support, Fotofab is ready to transform your concepts into reality. Discover the precision of Fotofab’s brass etching and get a quote today.

Brass Chemical Etching Process

Brass is a binary alloy composed of Copper and Zinc. It is similar to Bronze and valued for its workability, hardness, corrosion resistance, and attractive appearance. The metal is easily machined and formed into desired shapes while retaining high strength. Acid etching for Brass components is ideal for the automotive, artisanal metalworking, music, appliance, and sanitary industries.

Chemical etching brass is a highly effective method for producing durable designs capable of withstanding harsh indoor and outdoor environments. Typically utilizing ferric chloride, a potent caustic chemical, the process selectively etches unprotected parts of the brass surface, allowing for the creation of intricate designs or images tailored to specific project requirements.

Whether you’re etching a brass plate or a brass sheet, this technique offers precision and versatility compared to other etching processes. By leveraging the unique properties of brass, such as its corrosion resistance and malleability, chemical etching ensures that the resulting designs maintain their integrity and aesthetic appeal over time, making it an ideal choice for a wide range of applications in precision metal manufacturing.

Characteristics of Brass

- Wear and spark resistant

- Good thermal and electrical conductivity

- Low friction and non-magnetic

- Low melting point

- Acoustic properties that are desirable in the manufacturing of musical instruments

- High malleability, workability, and durability

A step-by-step process for chemical etching brass:

1. Prepare the Brass Plate: Start with a clean, bare brass plate. Ensure that the surface is free from any contaminants, such as oils or dirt, as this can affect the quality of the etching.

2. Design Preparation: Create or select the design you want to etch onto the brass plate. This design can be generated using graphic design software and printed onto a transparent film using a laser printer.

3. Toner Transfer: Place the printed design onto the bare brass plate, aligning it accurately. Apply heat and pressure using a laminator or iron to transfer the toner from the film onto the brass surface. This creates a resist mask, protecting the areas you want to keep intact during the etching process.

4. Brass Plate Cutting (Optional): If the brass plate is larger than needed, you can use a laser cutter to trim it down to the desired size, ensuring precise dimensions for your project.

5. Prepare the Etchant: Choose a suitable etchant for brass, such as ferric chloride, and prepare it according to the manufacturer’s instructions. When handling the etchant, wear appropriate protective gear, including gloves and goggles.

6. Etching: Submerge the brass plate into the prepared etchant solution. Monitor the etching process closely, as the duration can vary depending on factors such as the concentration of the etchant and the desired depth of etching. Agitate the solution periodically to ensure even etching.

7. Rinsing and Neutralization: Once the desired depth of etching is achieved, remove the brass plate from the etchant solution and rinse it thoroughly with water to stop the etching process. Submerge the plate in a solution of baking soda and water to neutralize any remaining acid.

8. Cleaning and Finishing: Carefully remove the toner resist mask from the brass plate using a suitable solvent, such as acetone or lacquer thinner. Clean the plate thoroughly to remove any residue from the etching process. Finally, inspect the finished plate to ensure that the etched design meets your specifications.

Fotofab is committed to quality.

Applications of Acid Etched Brass Services

The alloy exhibits a wide range of strength and hardness, ductility, electrical and thermal conductivity, and corrosion resistance properties when the levels of Copper, Zinc, and other metals are varied. Brass chemical etching is ideal for various applications, including:

- EMI/RFI shields

- Low profile shields

- Standard shields

- Covers

- Connector pins

- Shims

- Washers

- Injectors

- Taps

Other Factors

- The cold rolling process deforms brass’ internal grain structure, resulting in a much stronger and harder metal

- The proportions of Copper and Zinc can be varied to achieve different mechanical and electrical properties

- Nuts, bolts, and other threaded components are not parts that Fotofab manufactures

- Brass, with low Zinc content, can be easily cold worked, welded, and brazed

- A high Copper content enables Brass to form a protective oxide layer on its surface that guards against corrosion

- Brass is often used for its aesthetic appeal

Leveraging Brass with Fotofab

Our dedication to producing the highest quality precision metal components through chemical etching is reinforced by our certifications (ISO & AS9100D, ITAR Registration, RoHS compliance). Fotofab stands ready, whether for rapid prototyping or full-scale production of brass components.

Contact Our Precision Etching Experts today to discuss how we can integrate Fotofab’s advanced brass etching capabilities into your next metal component project.