This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Chemical Etching Stainless Steel

Stainless Steel, an iron-based alloy enriched with Chromium and Nickel, is known for its exceptional physical strength and resistance to corrosion.

Fotofab specializes in the chemical etching of stainless steel alloys, including the 301, 302/304, 316/316L, and 400 series, catering to a broad spectrum of applications and industries.

300 and 400 Series Stainless Steel Chemical Etching

The Society of Automotive Engineers (SAE) designates a variety of Steel and Stainless Steel types based on standard compositions and metal properties. They have developed a three-digit numbering system to identify each type.

Type 304 (also called 18-8) is the most common type, composed of Steel, plus 18% Chromium and 8% Nickel. Stainless Steel is an excellent choice for applications in electrical and electronic industries where it is in contact with moisture or other corrosive elements.

Our photo etching process, leveraging the precision of photochemical machining, allows us to create intricate designs that can withstand harsh indoor and outdoor environments. Our process uses a strong caustic chemical to etch into unprotected metal parts or a metal surface to create a design or image formed to your project’s specifications.

Characteristics of Stainless Steel

Stainless steel stands out for its:

Corrosion Resistance:

Tarnish-resistant and capable of withstanding harsh environments.

Thermal Conductivity:

Surpasses steel, ensuring efficient heat distribution.

Electrical Conductivity:

Exhibits low conductivity, suitable for specific electrical applications.

Magnetism:

Offers both magnetic and non-magnetic alloys for diverse applications.

Formability and Temperature Performance:

Exceptional in both formability and high-temperature scenarios.

Stainless Steel Grades We Work With

At Fotofab, our photochemical machining process encompasses a diverse array of stainless steel grades, each selected for its unique properties to meet the specific needs of various applications. Understanding the characteristics of different stainless steel grades ensures the optimal choice for your project, enhancing performance and durability.

Stainless Steel (300 Series)

The 300 series is the cornerstone of stainless steel used in chemical and metal etching processes everywhere, representing about 70% of the stainless steel produced worldwide. Predominantly made from a blend of 18% chromium and 8% nickel, these alloys are renowned for their:

- Exceptional Corrosion Resistance: Ideal for use in environments where rust and corrosion resistance is paramount.

- Outstanding Formability: This makes it the preferred choice for a wide range of manufacturing processes.

- Superior Weldability: Ensures ease in joining and fabrication.

- High-Temperature Resistance: Suitable for applications involving elevated temperatures.

Popular grades in the 300 Series:

- 304 (18-8): Known for its versatility across various environments.

- 316/316L: Offers enhanced resistance against chlorides and acids, making it perfect for more stringent conditions.

- 301: Known for its high strength and resilience, suitable for spring and structural applications.

- 302: Offers a slightly higher carbon content than 304 for increased strength.

- 321: Adds titanium to the mix for improved high-temperature stability.

Stainless Steel (400 Series)

The 400 series is distinguished by a higher carbon content, which is introduced to improve hardness and strength. While offering different characteristics compared to the 300 series, the 400 series is notable for its:

- High Strength: Provides excellent wear resistance and durability.

- Moderate Corrosion Resistance: Suitable for less aggressive environments.

- Magnetic Properties: Makes it useful in applications where magnetic functionality is required.

- Heat Treatability: Allows for customization of mechanical properties to specific needs.

Popular grades in the 400 Series:

- 410: Balances wear resistance with corrosion resistance.

- 416: Designed for enhanced machinability.

- 420: Known for high hardness after heat treatment.

- 430: Offers good corrosion resistance with exceptional formability.

- 440: High carbon content for maximum hardness and strength.

Special Stainless Steel Grade Variations

Fotofab also works with specialized stainless steel grades tailored for specific applications:

- 17-4 (SAE Type 630) and 17-4 PH: These are precipitation-hardening grades that combine high strength and corrosion resistance, ideal for aerospace, chemical processing, and other critical applications.

- Full and Half Hard, Annealed: These conditions adjust the material’s hardness and formability to fit the project’s requirements.

Our expertise extends beyond these listed grades. Fotofab’s commitment to versatility and quality ensures we can accommodate your stainless steel etching needs, regardless of the grade. For more information on our full capabilities and how we can assist with your specific material requirements, please contact us.

Fotofab is committed to quality.

Acid Etching for Stainless Steel Applications

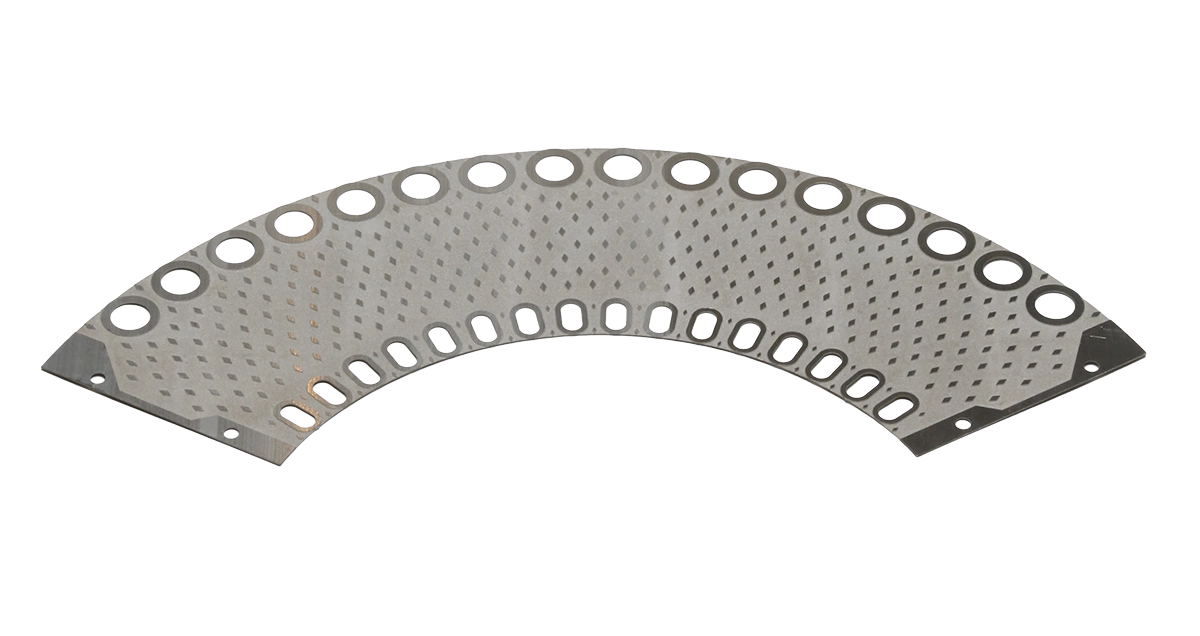

Stainless Steel Etching is excellent for applications that come in contact with moisture and other corrosive elements because of its anti-corrosive characteristics and tarnish-free surface. It is often used for components in commercial applications and industry for its strength, temperature corrosion resistance, and appearance.

Stainless Steel products etched and fabricated by Fotofab include:

- Medical instruments and device components

- Autoclave instruments and blades

- Masks

- Washers and shims

- Filters or screens

- Fuel Cell Plates

- Reflective optical components and light baffles

- Optical encoders

- Shielding

- Flat springs

- Mechanical parts

- Identification plates

- Enclosures

- Semiconductor components

Other Factors

- There are more than 60 grades of stainless steel, which can be categorized into 5 series based on their alloying elements.

- As a material to accept various fabrication methods, stainless steel can be more challenging than softer metals.

- The average carbon footprint of stainless steel is estimated to be 2.90 kg of CO2 per kg of stainless steel produced.

Fotofab’s Commitment to Quality

Fotofab is dedicated to delivering quality precision metal components, backed by our certifications, including ISO & AS9100D, ITAR Registration, and RoHS compliance. Our photochemical machining process is capable of handling metal thickness ranging from extremely thin to robust plates, ensuring precise dimensional tolerances and superior part configurations. Whether your project demands rapid prototyping or full-scale production of stainless steel components, our experts are ready to assist.

Contact Our Precision Etching Experts today to discuss how we can integrate Fotofab’s advanced stainless steel etching capabilities into your next metal component project.