This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Chemical Etching Aluminum

Aluminum is a versatile, naturally corrosion-resistant, and non-toxic metal known for its lightweight yet strong characteristics. Its exceptional corrosion resistance and durability make aluminum an ideal candidate for chemical etching, serving industries like aerospace, transportation, electronics, cookware, packaging, and construction with precision metal components.

Discover the advantages of acid etching for aluminum and how it can transform your project’s specifications by contacting us today!

Aluminum Chemical Etching

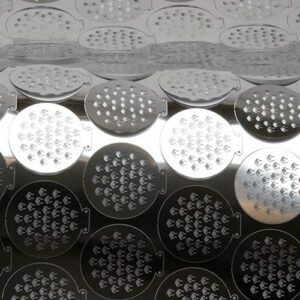

Fotofab’s Aluminum chemical etching process produces components that can withstand harsh indoor and outdoor environments. Acid etching uses a strong caustic chemical to etch the unprotected parts of a metal surface to create a design or image formed to your project’s specifications.

Choosing aluminum for photochemical machining has several benefits, making it a preferred material for a wide range of applications. Here are key reasons why aluminum is favored for chemical etching:

Characteristics of Aluminum

Lightweight and Strong:

Aluminum offers significant weight advantages, crucial for precision metal components in aerospace and automotive industries, without compromising on strength.

Malleability:

Its ease of fabrication through etching aluminum processes allows for diverse application use.

Conductive:

Aluminum’s excellent thermal and electrical conductivity is indispensable in electronics and semiconductor applications, further enhanced by chemical etching aluminum.

Reflective and Corrosion-Resistant:

Its ability to reflect light and resist corrosion makes aluminum a favored choice in aluminum etching for functional and aesthetic applications alike.

Why is Photochemical Etching Preferred for Aluminum Alloys?

Precision:

Achieving intricate designs with tight tolerances unattainable through traditional machining.

Efficiency:

The process is cost-effective, reducing the need for expensive hard tooling and offering quick turnaround times.

Integrity:

Maintaining the aluminum’s integrity, is essential for applications requiring the metal’s full suite of properties.

Aluminum Grades We Chemically Etch

Aluminum is used for both industrial and non-industrial applications, but it can be difficult to choose the right grade for your project. Below is a list of common Aluminum grades we chemically etch at Fotofab:

Alloy 1100

- Commercially pure wrought aluminum with 90% aluminum

- Mechanically the strongest aluminum alloy

- Soft, ductile, and excellent workability

- Non-heat-treatable

- Corrosion resistant

- High thermal and electrical conductivity

- Applicable in heat exchanger fins, dials and nameplates, and chemical processing parts

Alloy 2024

- Copper is the primary alloying element

- Used in applications that require a high strength-to-weight ratio

- Fatigue resistant

- Poor corrosion resistance

- Mechanical properties dependent on the temper of the material

- Applicable in aircraft structural components

Alloy 3003

- Most widely used Aluminum alloy

- Commercially pure Aluminum with added Manganese to increase strength

- Good workability

- Corrosion resistant

- Applicable in decorative trim, tanks, and chemical equipment

Alloy 5052

- Highest strength Aluminum alloy of the non-heat-treatable grades

- Alloyed with Magnesium and Chromium

- High fatigue strength

- Saltwater and marine atmosphere corrosion-resistant

- Excellent workability

- Applicable in aircraft components, home appliances, marine industry parts, and food processing equipment

Alloy 6061

- Precipitation-hardened Aluminum alloy

- Most versatile of the heat-treatable Aluminum alloys

- Great range of mechanical properties

- Corrosion resistant

- Good workability in the annealed condition

- Applicable for aircraft and automotive structural components

Fotofab is committed to quality.

Applications of Acid Etched Aluminum

Aluminum’s combination of low weight, relative strength, conductivity, and corrosion resistance makes the metal ideal for a variety of applications. Some etched aluminum use cases include:

Automotive and Aerospace Industries:

Where lightweight, durable parts like EMI/RFI shielding and structural components are required.

Producing microelectronic conductors, tags, and nameplates that benefit from aluminum’s excellent conductivity and etching precision.

Medical Devices:

Aluminum etching is crucial for creating components where precision and minimal weight are key, including surgical instruments and device casings.

Renewable Energy:

In solar panels and wind turbines, etched aluminum parts play a pivotal role due to their naturally corrosion-resistant nature and efficiency in heat dissipation.

Industrial Applications:

Creating high-wear components, control panels, and data-rating plates, leveraging aluminum’s durability and malleability.

Other Factors

- After Iron, Aluminum is the second-most widely used metal in the world

- The metal is ideal for operations including drilling, cutting, punching, welding, rolling, forming, and bending, due to its malleability

- Aluminum reacts with oxygen in the air to form an extremely thin layer of oxide, which is self-repairing, dense, and provides corrosion protectionIt does not rust because it contains no Iron, making it attractive for outdoor applications where moisture is a problem

- It does not rust because it contains no Iron, making it attractive for outdoor applications where moisture is a problem

What is Aluminum Etching and How Does it Work?

Aluminum etching, a form of photochemical machining, is a precise manufacturing process that uses chemical reactions to remove selected areas of metal. The process begins with coating aluminum plates in a light-sensitive photoresist before a photographic stencil of the desired image is applied. When exposed to UV light, the photoresist hardens where the design is, protecting these areas during the etching process.

The metal surface is then exposed to a controlled acid etchant, such as Ferric Chloride acid, which dissolves the unprotected metal, leaving behind the desired aluminum components with intricate designs and without affecting the properties of the metal, such as heat-affected zones seen with laser etching.

Leveraging Aluminum’s Versatility with Fotofab

Our dedication to producing the highest quality precision metal components through chemical etching is reinforced by our certifications (ISO & AS9100D, ITAR Registration, RoHS compliance). Fotofab stands ready, whether for rapid prototyping or full-scale production of aluminum components.

With aluminum being the second-most widely used metal globally, its applications are nearly limitless. The Fotofab precision etching process features a trio of fundamental improvements over other manufacturers, including reduced costs, faster speeds, and higher precision parts.

Contact Our Precision Etching Experts today to discuss how we can integrate Fotofab’s advanced aluminum etching capabilities into your next metal component project.