Why Photochemical Etching is Ideal for Photonics Applications

Photonics is critical in telecommunications, medical devices, aerospace, measurement, and consumer electronics, enabling the functionality of devices and systems that play a crucial role in our everyday lives. As the demand for miniaturized and highly efficient photonic components increases, manufacturers continually seek innovative methods to ensure precision and reliability when producing these intricate parts.

Photochemical etching (PCE) has emerged as a superior process for manufacturing photonic components for various industries. It can produce highly precise, intricate geometries with exceptional material versatility and scalability , making it the ideal choice for applications requiring high-performance components.

With more than 50 years of experience, Fotofab leads the way in delivering custom and standard thin, chemically etched metal parts and components for the optics and photonics industry. Our precision photochemical etching process produces parts used in cutting-edge optical devices with unparalleled accuracy.

This article explores the advantages of photochemical etching for photonic component manufacturing, key applications, and how Fotofab’s expertise ensures unmatched precision, reliability, and efficiency.

What is Photonics?

Photonics and optics span a wide range of the electromagnetic spectrum, from ultraviolet and visible light to infrared and beyond.

Industry applications of precision optics impact nearly every aspect of modern life, from weather and climate monitoring to the fabrication of new automobiles, from advanced agriculture to vision correction. By manipulating light with precision lenses, glass components, prisms, and intricate optical forms, our metal precision-engineered parts are integral to the performance of optical systems and help our customers drive innovation across diverse fields.

As a leading optical components manufacturer, Fotofab’s expertise extends to creating specialized parts for enhanced functionality and optimizing every aspect of optical system design. With advanced optical engineering techniques and state-of-the-art equipment, Fotofab is your trusted partner for precision optics solutions.

Why Photochemical Etching is Perfect for Photonics

The manufacture of photonic components requires a process that is accurate, supports material diversity, and keeps costs low. Photochemical etching offers these benefits, making it a valuable technique in the photonics industry. In addition, the turnaround time from concept to finished part and full scale production can be measured in days instead of weeks.

This trusted process is particularly effective in creating microstructures for laser diode assemblies, ensuring optimal performance and minimal thermal interference. In addition to being compatible with a wide range of materials, this process is also suitable for materials that have favorable photonic characteristics. Optical applications often use aluminum because it has a high reflectivity, while plating with gold, silver, or palladium is also possible. Copper’s low electrical resistance makes it ideal for electrical circuits. The high accuracy of photochemical etching also makes it perfect for producing critical components like apertures, masks, and spacers, where precise geometries and smooth edges are essential for efficiency and reliability.

Let’s examine the main reasons why photochemical etching is the superior machining process for photonic components:

Precision & Customization

For the fabrication of photonic components, photochemical etching offers an extremely high level of accuracy and the ability to create incredibly intricate designs. It supports complex geometries and fine tolerances that are essential for parts used in applications like waveguides and photonic integrated circuits (PICs). The process ensures that each part is manufactured to exact specifications, enabling improved performance in light manipulation and detection.

Material Versatility

The photonics industry relies on materials such as stainless steel, nickel alloys, and other metals that are often challenging to machine using traditional methods. Photochemical etching works with a wide range of materials, ensuring compatibility without compromising structural integrity or optical performance. This versatility allows manufacturers to optimize the properties of photonic components for specific applications.

At Fotofab, we work with several materials commonly used in optics, including stainless steel, copper, aluminum, and other specialized metals. We deliver robust, precision components tailored to the diverse requirements of critical applications.

Cost-Effectiveness & Scalability

Whether prototyping or producing components at scale, photochemical machining is a cost-effective solution, with tooling costs significantly lower compared to methods like stamping or CNC machining. Re-designs do not require new tools, reducing time and effort significantly. PCE’s scalability also supports small-batch customizations and large-scale production runs, making it ideal for various project sizes.

Surface Quality

Photochemical etching is an ideal process for manufacturing photonic components due to not effecting surface quality. The process delivers smooth, burr-free edges and surfaces, which are critical for minimizing optical distortion and ensuring precise light transmission in photonic devices.

With the ability to pre-etch for reduced reflectivity or maintain the material’s inherent reflectivity, photochemical etching offers unparalleled flexibility for optical applications.

The process also avoids the use of thermal or mechanical stress, preserving the material’s original properties and ensuring that components integrate seamlessly into photonic integrated circuits and systems. This high level of surface quality directly contributes to enhanced performance and reliability in advanced photonics.

Eco-Friendly Manufacturing

Photochemical etching (PCE) supports sustainability initiatives by minimizing waste and using environmentally friendly processes. The precise chemical etching process removes only the necessary portions of raw materials, unlike CNC machining, which generates significant scrap material. This significantly reduces material waste by utilizing almost the entire sheet.

Along with preserving the integrity of the material, PCE also eliminates mechanical force or heat, reducing the need for resource-intensive post-processing steps. Waste water is treated to remove heavy metals before being returned to the water distribution network. Its ability to produce intricate designs without secondary operations further minimizes energy and material consumption, making it a truly sustainable manufacturing solution.

The high precision and design flexibility delivered by PCE are key advantages for industries seeking to meet stringent environmental standards.

Want to learn more about the broad range of advantages photochemical machining offers? Download our free Photochemical Machining (PCM) Whitepaper.

This whitepaper explains:

- What photochemical etching (PCM) is, and the steps involved in its process.

- The types of metals that can be etched by PCM.

- Limitations of PCM in regards to part size and metal thickness.

- What industries can benefit from using PCM over traditional machining processes.

- The different application components created through the PCM process

Common Applications of Photochemically Etched Photonic Components

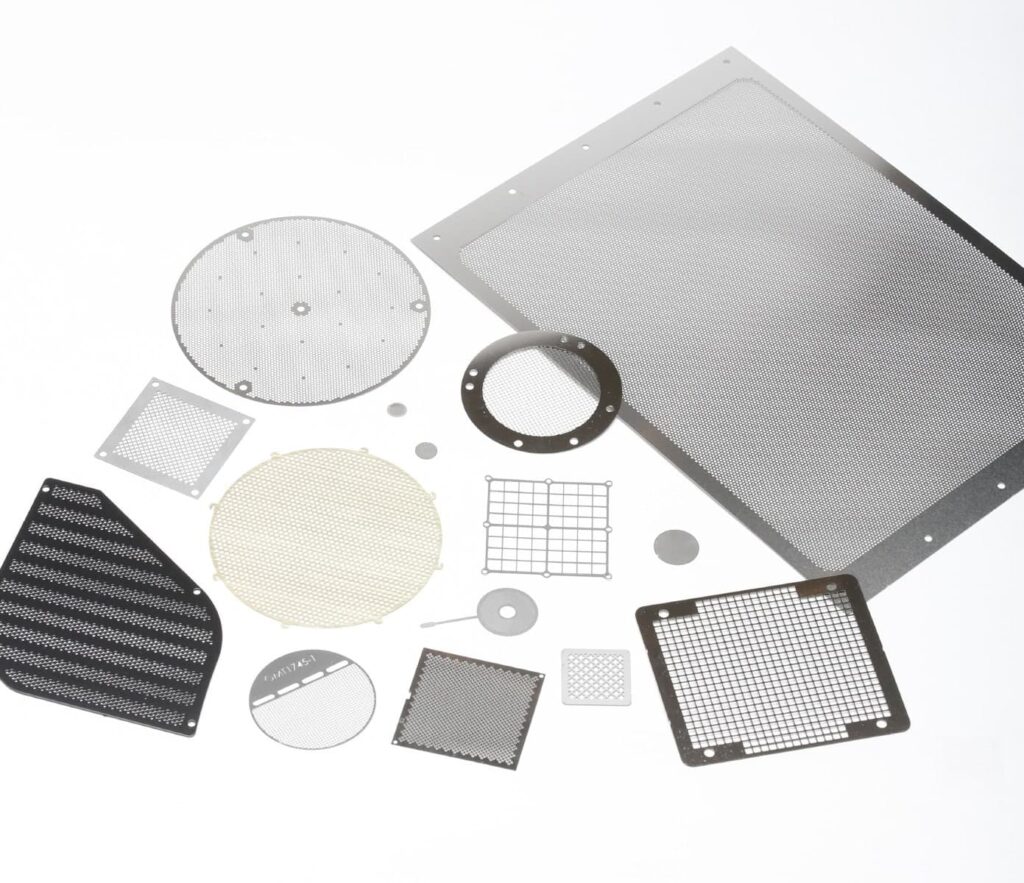

With its high precision and material versatility, photochemical etching has become essential in producing various photonic components.

Key applications include parts for:

- Waveguides: These structures guide light within photonic systems and require intricate geometries and smooth surfaces for optimal performance.

- Reflectors and Light Filters: Etched metal components ensure precise light manipulation and filtering in optical systems.

- Photonic Integrated Circuits (PICs): PCE enables the creation of high-precision, compact components essential for integrating photonics and electronics.

- Microlenses and Gratings: These intricate parts benefit from the tight tolerances and customization possible with photochemical machining.

- Apertures: Photochemical etching delivers highly precise and consistent openings, ensuring optimal light transmission control in photonic and optical systems.

Industries such as telecommunications, aerospace, and medical devices rely heavily on photochemically etched photonic components to meet stringent performance and precision requirements. These components are pivotal in enabling cutting-edge innovations, from fiber optic networks to advanced imaging systems.

Beyond just aerospace applications, photochemical etching is increasingly utilized in medical, defense, electronics, technology and other applications, where high precision and reliability are essential for achieving optimal functionality in complex systems.

As a leading optical components manufacturer, Fotofab specializes in:

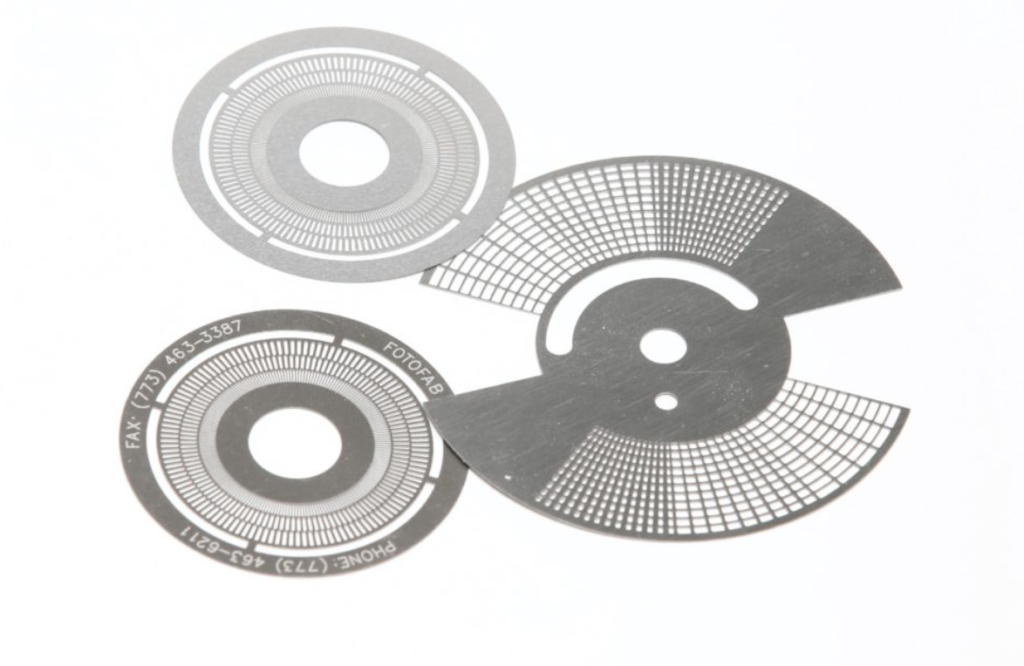

- Optical encoders: We specialize in manufacturing precision optical encoders, including encoder discs and scales designed to meet the rigorous demands of robotics, industrial automation, and medical devices. With unmatched accuracy and durability, our custom-made optical encoders ensure precise motion control and positioning, enabling advanced performance in critical applications.

- Thermal Management Components: We produce precision thermal management components, including custom-engineered heat sinks and mounts designed for high-power optical systems. These components ensure optimal heat dissipation and stability, enhancing the performance and longevity of advanced optical technologies in demanding applications.

- Custom Optics Components: We lead the way in producing custom optics components, including precision-engineered beam splitters, apertures, and bespoke solutions tailored to specialized applications. Our advanced fabrication techniques and commitment to quality ensure exceptional performance and reliability for even the most demanding optical systems.

Other common components we etch for the photonics and optics industry include:

- Reflectors and light baffles

- Light diffusion screens

- Filters

- Heat sinks

- Equipment faceplates

- Laser mounting components

- Fiber optic guides

- Optic-based sensors for prevention and detection

- 5G wireless network components

- Optical fiber components for communication networks

- Consumer electronics components

Fotofab’s Expertise in Photochemical Etching

Fotofab brings decades of expertise, advanced technology, and a customer-first approach to photochemical etching. Specializing in high-precision manufacturing, our expert team consistently delivers superior photonic components tailored to meet the exact needs of diverse industries. Here’s what sets Fotofab apart:

Unmatched Precision and Quality

We use state-of-the-art digital imaging machines to accurately map designs onto metal sheets. This ensures consistency across production runs, eliminating variations and delivering high-quality precision parts that perform reliably in demanding applications.

Reduced Costs and Faster Turnaround

Our precision etching process is engineered for efficiency. By minimizing material waste and streamlining production, we offer cost-effective solutions with faster lead times compared to traditional manufacturing methods.

Material Sourcing and Domestic Manufacturing

All materials are sourced, and manufacturing is conducted entirely within the United States, ensuring quality control and reliable supply chains. Our commitment to local production also supports sustainability and promotes ethical business practices.

Comprehensive Capabilities

From prototyping to full-scale production, we accommodate projects of all sizes. The expertise we offer spans a wide range of materials and finishes, metalforming & plating, black oxide for dulling and e-polising for brightening, ensuring every component meets the unique requirements of its intended application. Whether creating waveguides, photonic integrated circuits, or reflectors, our components enhance performance and durability.

Certifications and Quality Assurance

We have a company-wide commitment to quality. Our certifications, including ISO 9001:2015 & AS9100D, ITAR registration, and RoHS compliance, reflect our dedication to quality and regulatory adherence. Each project undergoes rigorous quality control to ensure it meets the highest standards.

The Role of Photonics in Shaping Modern Life

When it comes to photonics and optics, their applications are impacting nearly every aspect of modern life.

As technology continues to advance, the role of chemical etching in manufacturing photonic components is expected to expand. While its advantages depend on the specific application, chemical etching often outperforms traditional machining methods by delivering unmatched precision, material versatility, and cost-effective scalability. This process excels at producing intricate geometries, smooth surfaces, and high-precision features, making it an ideal choice for complex and demanding designs.

As a trusted leader in precision-etched metal parts for over 50 years, Fotofab has built a reputation for producing chemically etched precision photonic components for leading industries like telecommunications, aerospace, and medical devices. By leveraging advanced etching techniques, we consistently deliver high-quality, burr-free components with complex designs and tight tolerances, which are ideal for a wide range of photonics applications.

From optical encoders to heat sinks, our solutions are critical for applications in medical sciences, security, aerospace, automotive, defense, manufacturing, industrial, technology, lighting, test and measurement, and telecommunications.

If you want to explore the benefits of precision optical manufacturing solutions, Fotofab can help. By partnering with our expert team, you get affordable, high-quality precision part solutions for optical and photonics devices tailored to meet your needs.

Contact us today to find out how to reduce your costs while increasing your quality, or request a quote.