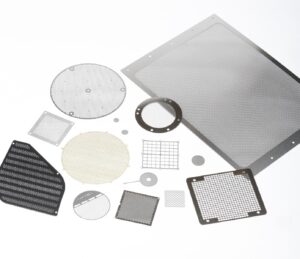

Custom Screens

Etched screens offer design flexibility and cost efficiency to meet your demanding requirements.

Why chemically etch screens?

- Chemical etching also provides consistent hole opens throughout the part.

- Compared to using a mesh (woven) screen, Fotofab’s process provides a flat pattern where particles are less likely to become trapped in the weaving.

- A flat pattern also provides consistent hole openings whereas woven screens can stretch and become distorted.

- Fotofab screens can be designed in a variety of shapes, percentage open-area, and in a variety of metals. Brittle metals and thin foils are much easier to etch than stamp, or machine in other traditional forms of manufacturing.

- A new part can be tooled up within a couple of hours and parts can be manufactured the same day. Artwork, or photo tool, is one of the first steps needed to chemically etch your screen application.

- The photo tool, which usually costs about $300, involves setting up the necessary artwork used to mask off certain areas of the metal allowing the features of your metal part to be precisely etched.

For more information on photo tools, chemical machining and the Fotofab process check out the etching page of our website or download our PCM Whitepaper. To read more on-screen hole patterns and designs, please request a screen design guide.

Typical Applications for Acid Etched Screens

Fotofab has manufactured screens in the medical, aerospace/defense, electronics, and food processing industries.

Applications range from using a stainless steel screen to assist in processing the all-American favorite ketchup to a high precision screen used on many of our nation’s military aircraft.

No matter how big or small the application is, industry-leading companies rely on Fotofab for quality metal parts and screens.

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.

Advantages to Fotofab

Fotofab has been a leading manufacturer in making precise metal parts and screens through photochemical etching for over 50 years. Fotofab is known for offering some of the fastest lead times around with standard parts taking 1 week from blueprint to shipment.

We also offer premium delivery services for 3-day and same-day turnaround. Fotofab also prides itself on offering excellent customer service as well as producing top quality metal parts. Fotofab is ISO 9001:2015 certified and ITAR registered.