Telecommunications Industry

As technology and work structures continue to change at an accelerated rate within the telecommunications industry, photochemical etching, or chemical etching, is a precise process that can keep up with the pace.

Photochemical Etching of Telecommunications Components

Complex, geometric parts are produced with the strictest of tolerances and configurations at higher volumes, faster rates, and affordable costs. Fotofab specializes in photochemical etching of various telecommunication components, including:

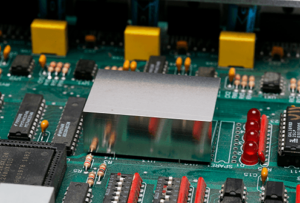

- Low-profile EMI/RFI shielding for mobile devices and telecom equipment

- UHF/Microwave antennas for satellite communications, surveillance radars, mobile devices, and wireless accessories

- Grounding springs, or spring fingers, used in small PCBs

- EMI shielding gaskets for networking gear, base stations for cellular networks, portable electronics, and handheld communication devices

- Fiber optical cables for voice, video, and Internet data transmissions

In addition, we offer custom and standard shielding products such as:

- Board-level EMI/RFI shields

- Shielded enclosures with snap-on dimple lids

- Custom prototype shielding with selective ventilation

Our Capabilities for the Telecommunications Industry

Telecommunications influences every part of our lives—from how we communicate to how we work, and to how we commute, shop, and relax. The integration of AI technologies, 5G networks, and the Internet of Things (IoT) is creating demand for increased bandwidth at higher efficiencies and lower latency rates.

Fotofab can quickly fabricate or prototype a variety of components at affordable prices that traditional processes cannot provide. From your CAD file, we can produce finished parts in one business day, without the typical expense of tooling.

Our team purchases materials from reputable suppliers, verifies compliance upon arrival, confirms accuracy with precision testing, and audits completed orders prior to shipment. From the moment an order is received, we are all accountable for the service.

Metals used in Telecommunications

With the current shifts happening in the digital landscape, new technologies will continue to be produced and used in telecommunications. While there are a variety of metal components used in the telecom sector, the most common metals include:

Fotofab is committed to quality.