This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Precision Machining Tabs

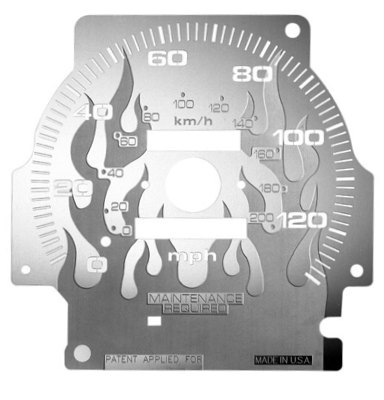

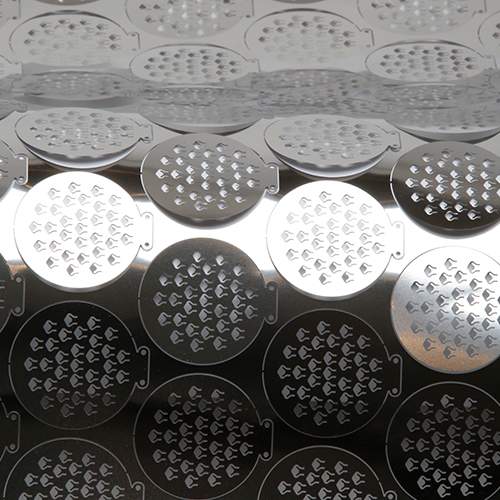

In most cases, your precision machined part will be etched from a sheet of metal. This allows tolerances to be tighter as the sheet runs through the acid for etching. Parts can be shipped in these webbed sheets or removed for immediate use upon delivery.

What are Tabs?

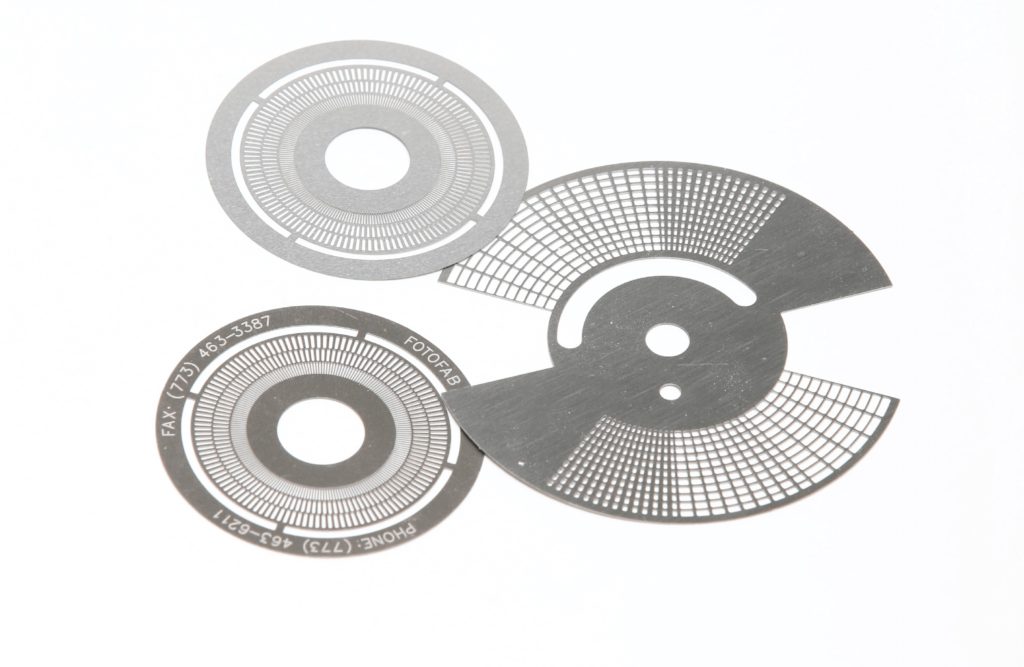

Metal parts are held in sheets by several small tabs which may leave a burr when detached. It is important to note that this burr is unlike a progressive die burr. Therefore Fotofab will refer to these “burrs” as tabs. There are two types of tabs used in the Fotofab Process: External and Recessed.

External Tabs

External tabs formed by precision machining will produce a break-off point that will leave a small part of the metal sheet on the part. If you have one of Fotofab’s business cards, you may be able to feel the external burr used on our cards.

Recessed Tabs

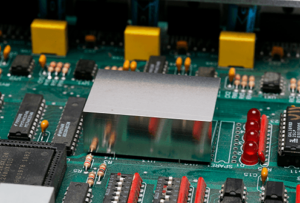

Recessed tabs formed by precision machining are similar to external tabs except that the break-off point will be recessed into the part. Use this option if your part cannot have any areas extend beyond its perimeter. Typical applications that use the recessed tab are metal parts such as encoder discs, washers, and other circular parts. RF/EMI shields will also use recess tabs so that the tab does not affect the fence’s attachment to the PCB.

Fotofab is committed to quality.

Design Guide to Photochemical Machining: Tabs

To provide the tightest tolerances, we recommend precision machining parts so that they remain within the metal sheet from which they are etched. The small amount of metal that is designed to bridge the part to its metal sheet is called a tab. Parts that are tabbed to remain in the sheet also allow for safer handling and easier inventorying.

Fotofab gives you the option of two different tab designs, depending on the edge requirements of your part. The upper figure to the right illustrates the general appearance and maximum tab dimensions of a part held to the sheet by an external tab after it has been removed from the sheet. The lower figure illustrates the general appearance and maximum tab dimensions of a part held to the sheet by a recessed tab after it has been removed from the sheet.

For thicker metal parts, Fotofab can design a small score line etched into one side of either an external or a recessed tab to facilitate the part’s removal from the metal sheet.

If your part’s outside edge requirements are critical, we can produce the part without tabs. We refer to an untabbed part as a dropout part. The benefit of a dropout part is that it will not have a tab because the part does not remain in the metal sheet during etching. However, a dropout part can be etched less consistently than a tabbed part, and therefore has a guaranteed dimensional tolerance of approximately +/-15% of the metal thickness with an absolute minimum of +/-.003″.

Depending on the strength of the metal chosen, typically only a part that is thicker than .010 inches (.254 mm) is a candidate for a dropout part. Note that a dropout part is more expensive to handle, inspect and package than a tabbed part, so consult with us prior to selecting this option.

What are my options if my part cannot have Tabs?

We can produce your metal part without placing any tabs to hold the part to the sheet. This is referred to as having drop-out parts. The benefit of going with drop-outs is clearly losing the tab, but since the parts are less stable (they are no longer tabbed into the sheet) we generally have looser tolerances on drop-outs. Additionally, the etching and stripping processes create a higher yield loss. Parts that make good candidates for drop-outs depend on metal thickness (the thicker the better), part design, and most importantly tolerances.