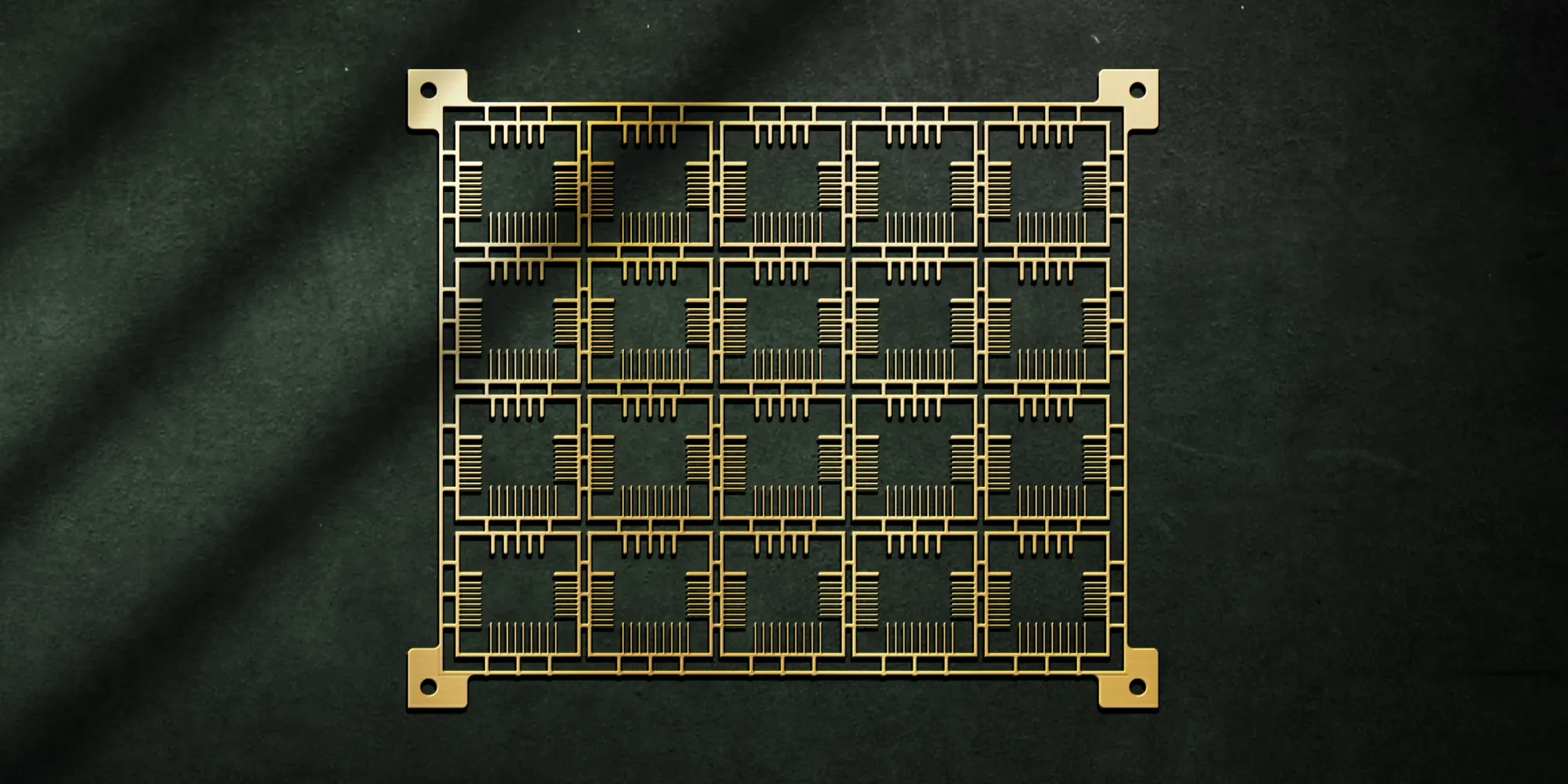

Photochemically Etched Lead Frames

Lead frames are essential components used in a variety of electronic devices across multiple industries. These precision components provide reliable electrical connections between the semiconductor chip and the external circuitry. Made from precision-manufactured metals, lead frames ensure excellent thermal and electrical conductivity, vital for the high performance and accuracy required in critical applications.

- Ensure stable and efficient electrical connections

- Dissipate heat effectively, maintaining device performance and preventing overheating

- Support efficient power and signal transmission

- Maintain durability and performance under extreme conditions

- Allow for high accuracy and consistency

- Enable the development of smaller, more compact devices

Superior Lead Frames for High-Performance Applications

Precision-manufactured lead frames are critical for providing the high performance and accuracy required in various applications. These powerful components ensure device reliability and safety, and are used in industries such as medical, aerospace, energy, and more.

With extensive experience in photochemical etching, Fotofab has developed specialized knowledge and techniques to produce superior-quality lead frames. Providing exceptional customer service and technical support, we assist clients through every stage of the project, from design to delivery.

Typical Applications of Photochemically Etched Lead Frames in Medical Devices

Medical applications are one area where the accuracy and durability of photochemically etched lead frames are essential. These components ensure stable electrical connections and optimal performance in critical devices.

Key applications of photochemically etched lead frames include:

Medical Imaging Equipment:

Critical in devices such as MRI machines, CT scanners, and X-ray equipment, ensuring accurate signal transmission and device functionality.

Diagnostic Devices:

Ensures reliable electrical connections and performance in devices such as blood glucose monitors, diagnostic sensors, and portable diagnostic equipment.

Implantable Devices:

Often used in pacemakers, defibrillators, and neurostimulators, where biocompatibility and precision are critical for patient safety.

Wearable Medical Devices:

Provides reliable electrical connectivity in compact forms for fitness trackers, heart rate monitors, and other wearable health monitoring systems.

Laboratory Equipment:

Ensures high performance and accuracy in precision laboratory instruments used in research and diagnostic laboratories.

Metals Commonly Used in Photochemical Etching of Lead Frames

Fotofab employs a variety of metals in the photochemical etching process to meet the stringent requirements of various industry applications.

Typical metals used for lead frames include:

Fotofab Advantages

With a commitment to quality, precision, and customer satisfaction, Fotofab has positioned itself as a leader in delivering high-precision components tailored to the stringent requirements of medical, aerospace, energy, and other critical industry applications.

Capable of rapid prototyping and production, we adhere to strict quality control standards and certifications, ensuring each product meets or exceeds industry benchmarks for performance and reliability.

Benefits of Photochemical Etching for Lead Frames

High-precision components are essential for the functionality and reliability of critical devices

Our proven photochemical etching process creates intricate and precise metal parts, making it ideal for producing lead frames with tight tolerances and complex designs required across industries.

Benefits of this precision process include:

High Precision:

Allows for the creation of intricate and complex designs with tight tolerances, essential for the functionality and reliability of critical devices.

Clean Edges:

Produces burr-free and clean edges, critical for the performance and safety of critical devices.

Cost and Time Efficiency:

Part complexity and the number of features do not affect the price and lead-time, making it an efficient choice for complex designs.

Stress-Free Process:

Unlike mechanical machining, photochemical etching does not induce stress or alter the material properties, ensuring the integrity of delicate components.

Design Flexibility:

Easily accommodates design changes and customizations in as little as 1 to 2 days, enabling rapid prototyping and production adjustments to meet specific requirements.

Material Efficiency:

Minimizes material waste, making it a cost-effective method for producing high-quality components.

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals.

Fotofab is committed to quality.

Photochemical Etching for Heat Exchangers

Fotofab has been chemically etching custom Heat Exchangers for over 50 years in a variety of applications in: