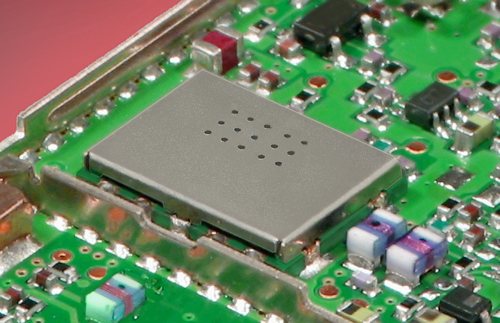

Low Profile EMI & RFI Shielding

RFI/EMI Shielding is produced in many different shapes and sizes. The increased demand for miniaturization means enclosures are getting smaller.

Fotofab’s unique photochemical etching process is well suited to make small or low-profile 5-sided enclosures, ideal for mounting on PCB boards.

For a standard formed can (without a trimming operation) we can produce low-profile EMI & RFI shields with a minimum internal height of .024″(.61mm) and a maximum wall thickness of .008″ (0.2mm).

With a secondary trimming operation we are able to produce RF Shields with a minimum internal height of .010″ (.254mm) and with a wall thickness of .008″(0.2mm).

Thinner or thicker materials may be specified for any shielding can, but we recommend staying below .010″(.25mm) for small or low-profile cans. It helps with bending but thinner material also takes up less space and has less mass.

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More