COVID-19 OEM Parts and Capabilities

Fotofab Remains Fully Operational

Yes, We’re Open! Fotofab manufactures essential parts for the medical market and has, therefore, remained open. As businesses begin reopening, the health and safety of our employees and customers is still our number one goal.

Fotofab products are made in the USA and distributed worldwide.

Fotofab remains fully operational–with room to grow production–as our hearts remain with those working the front lines of the COVID-19 pandemic. We continue to work with medical design engineers as we begin to work with the non-traditional companies who have turned their attention to the coronavirus fight.

Fotofab’s production and quality teams continue to tirelessly fabricate metal parts that aid in the relief effort. Their dedication help fill the supply-chain gaps so our customers’ needs are met around the world.

Today, our parts can be found in medical devices used for COVID-19 testing and ventilators in hospitals across the nation.

Standards and Certifications You Can Trust During COVID-19

Fotofab’s mission over the last 50 years has been to improve the photochemical etching process so that we can guarantee high-quality products are delivered to you, our customer. To accomplish our mission, we have built a strong quality team with with years of engineering and manufacturing experience, and paired them with state-of-the-art inspection equipment. This commitment to quality has led us to:

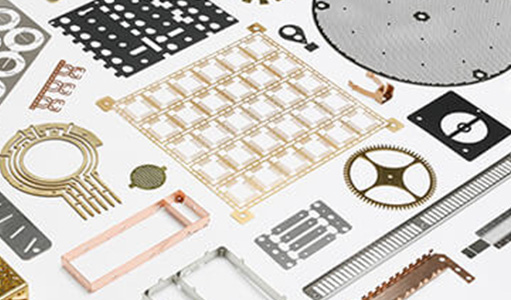

Photochemical Etched Parts for Ventilators and Medical Devices

Our photochemical etching process creates thin, precision metal parts that are critical for the medical industry. Standard and custom parts for masks, testing devices, and ventilators are available for delivery within 5 business days. Our production and quality staff remain on-site to manufacture crucial medical components including:

- RF Shields (standard sizes ready to ship)

- Washers

- Filters

- Flat Springs

- Shims

- Clips

Our quoting and order entry team are working remotely so prototyping remains quick and easy with our process. We are ready to discuss your project.

For updates on COVID-19, visit the Centers for Disease Control and Prevention.

Applications:

- Ventilators

- COVID-19 testing devices

- Essential medical procedure devices/instruments

- Defense detection

- Telecommunication components

Parts:

- RF Shields (standard sizes ready to ship)

- Washers

- Filters

- Flat springs

- Shims

- Clips

- Half-etched components

Additional Services During COVID-19

Fotofab offers a variety of value-added services for our photochemically etched metal parts, including:

- In-House Forming and 4-Slide Stamping

- Various Plating and Finishing Options

- Custom Packaging

We also offer diffusion (vacuum) bonding that allows smaller features in thicker material, as in medical device capillaries. This is not possible with laser cutting and can be time-consuming with machining.

We work with OEMs to deliver ready-to-use parts that are exact to print. In these stressful times, our team is doubling down to get quotes back within 2 business days and delivering parts in as little as 3 business days.

Materials

The metal used in our photochemical etching process is sourced from the United States and manufactured in our Chicago, IL location.