This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Blackening & Coating Services

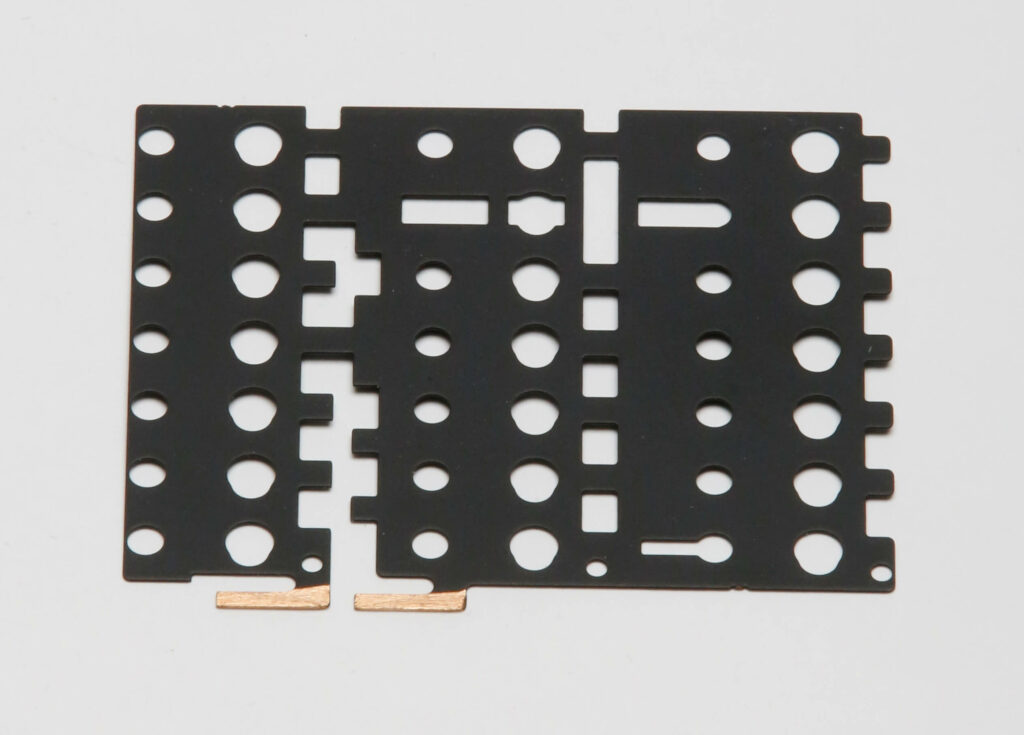

For over fifty years Fotofab has been an industry leader in high precision metal fabrication services. We offer an extensive list of blackening services as part of our value-added capabilities. These capabilities can be divided into three distinct types: chemical, coating, and electroplating. Specifically, the services we offer include:

- Chemical: Black Oxide

- Coating: Black Anodize, Black Paint

- Electroplating: Black Zinc, Black Nickel, Black Chrome

Blackening Services Overview

Chemical, Coating, Electroplating

The blackening of metal parts is commonly used to reduce the reflectivity of a metal or for decorative purposes. Reducing the reflectivity of a metal surface limits the amount of light that bounces back from a source emitting light to a part.

Black Oxide

Black oxide is a chemical conversion coating designed to resist corrosion and minimize light reflection. This type of blackening service can be performed on ferrous materials, stainless steel, copper, copper-based alloys, zinc, powdered metals, and silver solder. This can be useful in a number of fields, but our most common customers come from the aerospace, automotive, and military industries. One main benefit of black oxide is that no thickness is added to the treated metal, which is great for dimension critical parts.

Applications include:

- Face plates

- Electrical switches

- Firearm components

- Precision bearing and tooling

Black Anodize

Anodizing is an electrolytic passivation method designed to thicken the natural oxide layer on the surface of aluminum metal parts. This process serves several purposes. It strengthens the metal and increases its resistance to corrosion. It can also be used for aesthetic objectives.

Industries that use this process include aerospace, medical, and military.

Applications we often see include:

- Medical devices exposed to harsh cleaners

- External components exposed to intense light

- Heat sinks

- Aesthetic purposes

Black Painting

We offer black painting services per customer requirement. We perform this process on both sheets and individual pieces. Parts can be manufactured from most metals, including steel, stainless steel, aluminum, zinc, copper and copper-based alloys. The paint is secured through curing or baking. This method is primarily used for decorative purposes to minimize light reflection.

Black Zinc

Black zinc is an electroplating conversion service which provides a black chromate finish. This method is used to passivate steel, aluminum, zinc, cadmium, copper, silver, magnesium and tin alloys to increase corrosion resistance.

At Fotofab we offer both hexavalent and trivalent finishes, to comply with RoHS requirements. We provide this service most commonly for aerospace and military industries.

Applications we frequently see are:

Black Nickel

Black nickel is a second electroplating conversion service which provides a black chromate finish. This blackening service increases corrosion resistance, while maintaining electrical conductivity and reducing reflectivity. It is also used for decorative purposes.

Black Nickel is available in a bright or dull finish for a variety of materials, including steel, aluminum, zinc, brass, copper, silver, magnesium and tin alloys. It is common within the aerospace and military industries.

Applications include:

- Optics

- Solar panel components

- Weapons systems

This process is RoHS, REACH, ELV and WEEE Compliant.

Black Chrome

Black Chrome is a third electroplating conversion service which provides a black chromate finish. At Fotofab we can provide both bright and matte finishes, depending on each customer’s individual needs and preferences.

This method is used mostly for decorative and corrosion resistant purposes. We frequently provide this service for companies within the aerospace and military industries.

- Decorative features

- Wear/high temperature resistant components

Fotofab is committed to quality.