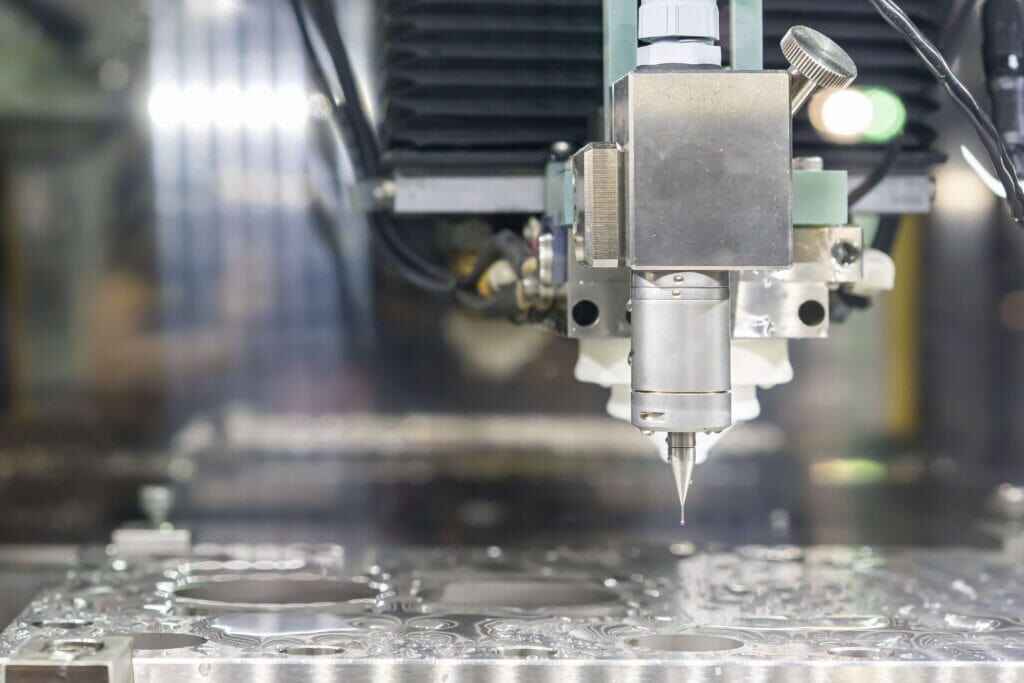

Wire EDM

Electron Discharge Machining (EDM) is a process where an electric current is used (sometimes in conjunction with a dielectric) to very precisely carry electrons of material away from the workpiece in the form of sparks.

Benefits of Wire EDM

(Electron Discharge Machining)

Fotofab utilizes Wire EDM services both in the process of producing our hard tools for forming and stamping operations and in conjunction with photo-etching to produce an individual feature that cannot be produced by etching alone.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More