Rapid Prototyping

Are you searching for the highest-quality, precision rapid prototyping parts?

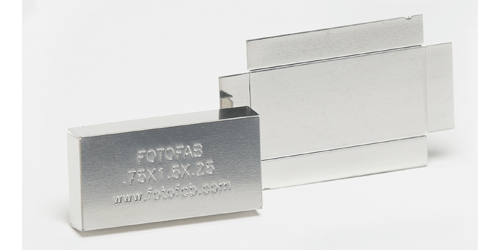

Fotofab has been an innovator in sheet metal component manufacturing for over half a century. Working with industry leaders in Aerospace, Defense, Medical Devices, Implantables, Industrial, and Electronics to fabricate high-quality, precision parts on time and within budget.

Precision Prototyping Services

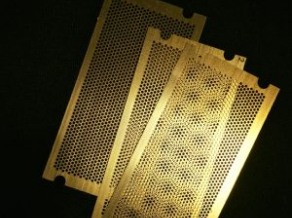

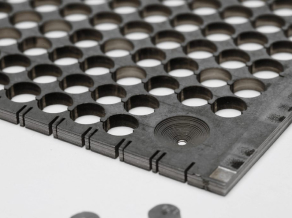

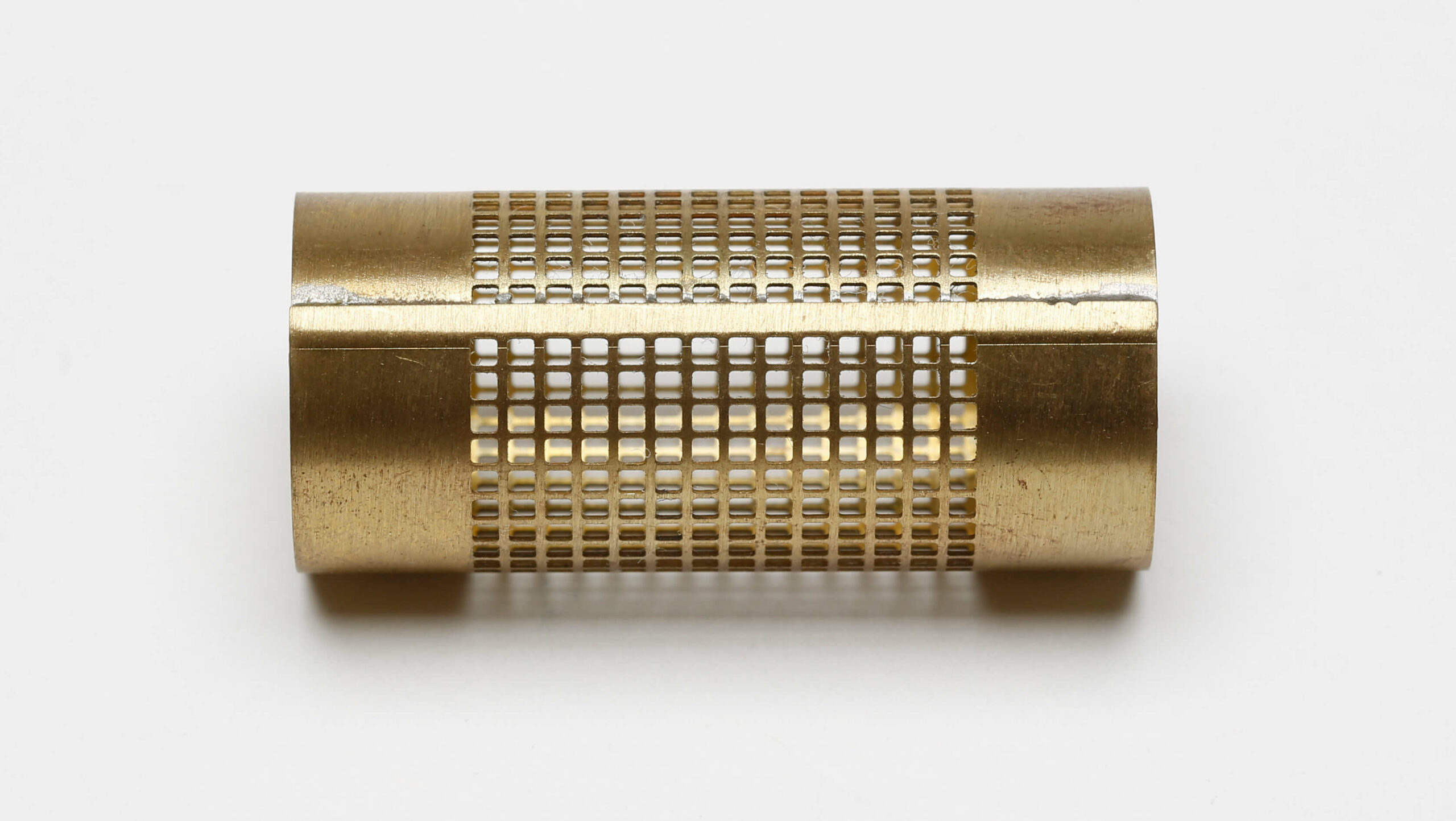

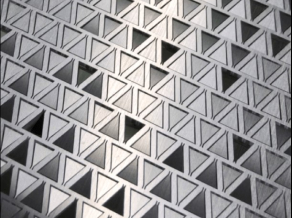

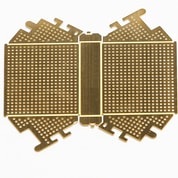

Fotofab specializes in producing your parts using methods such as chemical etching, stamping, forming, metal fabrication, and wire EDM.

Click on our rapid prototyping services to learn more about our rapid prototyping capabilities.

We also do all our manufacturing and material sourcing in the United States.

Fotofab is committed to quality.

Fotofab – The Only Thin Metal Rapid Prototyping Service You Need

When it comes to reliable production quality parts, there’s no one better in the business.

Fotofab offers industry-leading rapid prototyping technologies that provide functional prototypes designed for precision and durability. Our rapid tooling and fabrication services support quick turnaround for functional testing, ensuring each prototype meets exact specifications before full production.

With our industry-leading expertise, clients benefit from a functional physical model that accelerates development cycles and meets rigorous testing demands.

Our Proven Prototyping Process

Fotofab’s precision rapid prototyping process leverages advanced additive manufacturing techniques like precision chemical etching and fused deposition modeling to create high-quality prototypes with unmatched precision. By combining 3D printing capabilities with traditional methods like injection molding, Fotofab supports both low-volume production for rapid testing and high-volume production for full-scale manufacturing. This versatile approach enables seamless transitions from prototype to production, ensuring products are ready for market efficiently and accurately.

Unlike traditional manufacturing processes like stamping, CNC machining, and direct metal laser sintering, our proven process doesn’t negatively affect the metal’s integrity or compromise the performance of critical parts.

Advantages of Fotofab Rapid Prototyping

- Speed: Your custom Fotofab part can be made in 1-2 days and shipped in as few as three.

- Cost: Fotofab metal fabrications cost thousands of dollars less than machine-tooled parts.

- Precision: The Fotofab process of chemical etching metal offers center-to-center tolerances within .0005″.

- Experience: Fotofab has over 50 years of experience delivering metal fabrications to industry leaders.

- Guarantee: Fotofab parts are guaranteed to be free from defects in material and workmanship for 90 days.