Electropolishing Services

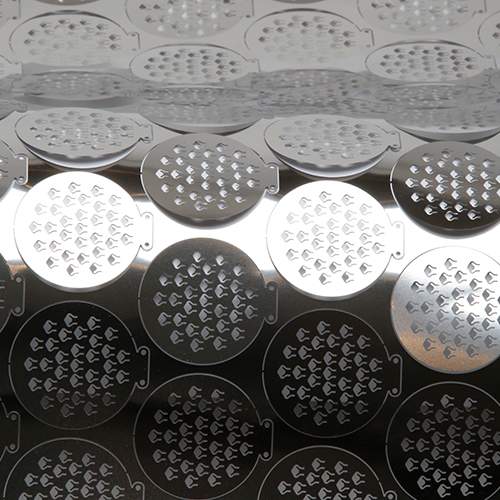

Since 1967, Fotofab has been an industry leader in high-precision metal fabrication services. This includes electropolishing.

Also known as anodic polishing or electrolytic polishing, electropolishing is an electrochemical polishing process. It employs a temperature-controlled bath of electrolytes (the anode) and a positive terminal of a DC power supply (the cathode) to remove material from a metallic workpiece.

Characteristics of Electropolishing

This process minimizes the surface roughness by smoothing out micro-peaks and valleys.

Electropolishing provides three distinct characteristics:

- Adhesion reduction

- Heat transfer

- Corrosion resistance

Electropolishing Advantages

Electropolished metals are used in a variety of industries including offshore oil exploration for downhole applications like drilling. These metals are equipped to handle frequent contact with corrosive materials normal in marine, oil, and gas settings. Electropolishing positively influences your bottom line by improving the material itself. Other advantages include:

- Increased production capacity

- Extended duty cycles

- Decreased product build-up

- Enhanced cleaning efficiency

Primarily, we provide these metal finishing services on stainless steel but can also provide them for:

Fotofab is committed to quality.