Photochemical Etching Dimensional Tolerances

The Fotofab metal etching process allows for highly complex part configurations and is suitable for parts ranging from extremely small to large.

Part Configuration

If the tolerances and dimensions fit our capabilities, there are virtually no limits on what we can create. We are experts in photochemical etching metal and producing parts with unmatched speed, affordability, and accuracy.

Overall Size of Parts

Fotofab typically etches parts from flat sheets of metal measuring 12 x 18 inches (305 x 457 mm). The metal etching process can produce parts that vary in size – from one piece taking up the whole sheet, to thousands of pieces per sheet. Depending upon the metal used, the largest part we can fabricate is 24 x 36 inches (482 x 914.4 mm). The smallest part Fotofab can make is dependent on the desired part’s thickness and geometry.

Part Tolerances

It is not possible to establish hard and fast rules regarding photochemical etching tolerances since so many factors are involved. Some of the variables that affect accuracy are the type of metal; the size of the sheet; the size of the production run; and the number of critical dimensions per part.

Center to Center Tolerances

Center-to-center accuracy is determined photographically, rather than by the metal etching process. This tolerance is typically considered to be within +/- 0.0005 inches (0.013 mm) over 6 inches (153 mm) for metal etching.

Dimensional Tolerances

An etched dimensional tolerance of +/- 10% thinner to +/- 20% thicker of the metal is considered acceptable by the industry. Parts that are designed with score lines for hand forming, such as RF and EMI shields, are an exception to this guideline. For hand-formed parts, the dimensional tolerance is approximately +/- 0.010 inch (0.254 mm), whereas parts that are formed with hard tooling must be determined on a part-specific basis.

Dimensional tolerances for dropout parts are different than for parts that remain on the sheet. Refer to the Tabs section for more information on having parts with or without tabs.

Formed Parts Tolerances

Fotofab’s standard tolerances for formed parts are +/- 0.005” (0.0127mm) and +/- 1° on all formed dimensions and some tolerances may be as tight as +/- 0.001” using more specialized tooling.

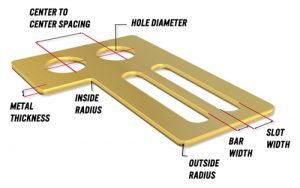

Photochemical Etching Radii

A typical minimum bend radius is equal to the metal thickness and radii as small as 0.002” (0.05mm) can be achieved if the geometry allows. Hand-formed parts will have a zero inside radius.

Fotofab is committed to quality.