Design Guides for Photochemical Machining

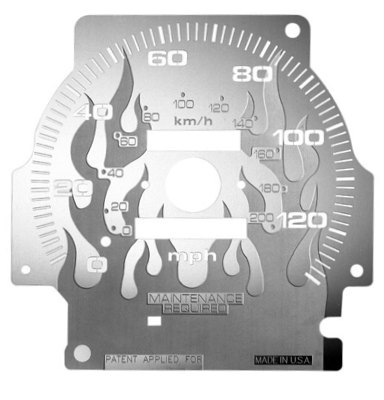

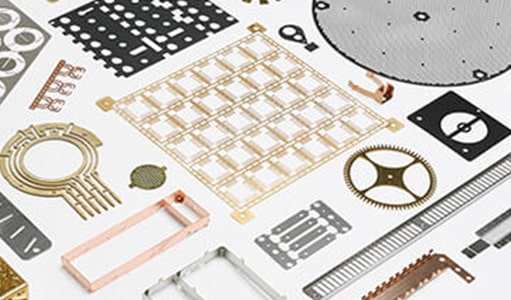

Fotofab’s design guides were created for those involved in designing or purchasing thin metal parts. Our chemical etching process places no limit on the complexity of a part’s configuration other than the size of the etched features relative to the thickness of the material.

Each of our design guides provides:

- An overview of the photochemical machining process

- General guidelines for designing photo-etched parts

- Engineering and cost advantages

- Design considerations of thin metal parts

- Tips for engineering drawings/sketches

Download design guides to learn more now!

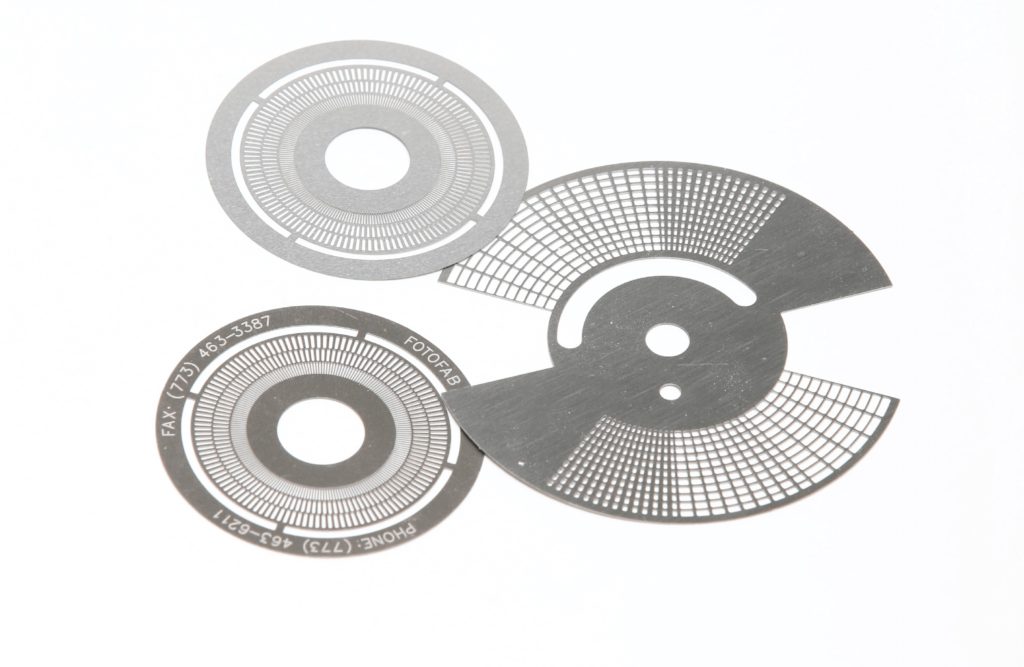

Advantages of Photochemical Machining

Photochemical machining, also known as chemical etching or acid etching, offers many advantages over traditional metal fabrication methods such as stamping and laser cutting. These benefits include:

- Speed of production

- Flexibility of complex part geometries

- Repeatability (from prototype to production)

- Cost-effectiveness

Compared to other fabrication methods, tooling costs are especially low.

Still Can’t Decide?

Are you unsure whether photochemical machining is right for your project? Check out this resource provided by the Photo Chemical Machining Institute (PCMI), for a more in-depth look at the benefits of our etching process. Click HERE AND DOWNLOAD PDF.

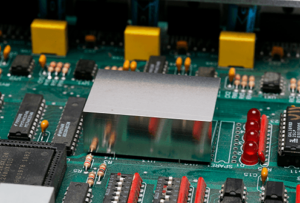

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.