Resources

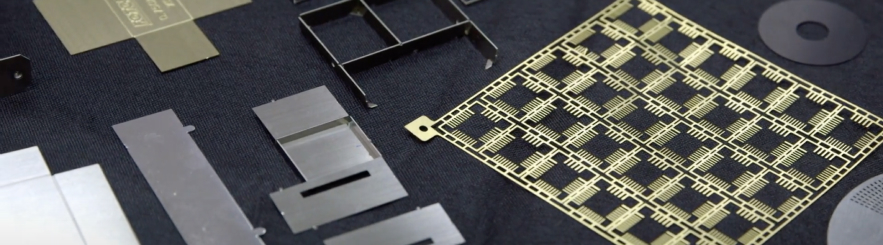

Fotofab uses the photochemical machining process to produce a wide variety of precision parts from thin metal sheets. Not many are familiar with the process, so our “Design Guide to Photochemical Machining” was created specifically for those who are involved with the designing and/or purchasing of metal parts.

Photochemical Machining Design Resources

The Design Guide provides you with:

- Engineering advantages of photochemical machining.

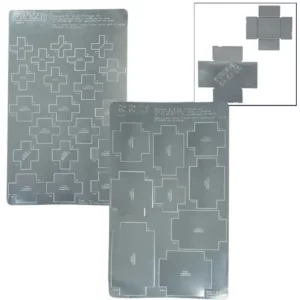

- Overview of our photochemical machining process.

- Considerations for the design of your thin metal parts.

- Considerations for your engineering drawings/sketches.

Fotofab offers free consultation and quotation for your specific designs and is available to assist you with your metal parts requirements. By designing with an awareness of our process capabilities, you will minimize the cost and delivery time of your metal parts, whether for prototyping or production.

Photochemical Machining Design Advantages

(Chemical Etching)

Design Advantages

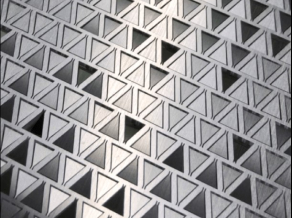

- Many intricate part geometries, like those found in fine resolution screens, can be photochemically machined easily and economically.

- Extremely thin metal can be machined without distortion; dimensional accuracy actually increases as metal thickness decreases.

- Physical properties of the metal, such as hardness, strength, and formability, are not changed by the process.

- Brittle metals, which often fracture during conventional stamping, are machined without difficulty.

- Magnetically soft materials can be fabricated while retaining their optimum permeability.

- Parts are inherently free of burrs.

Tooling and Delivery Advantages

- Tooling and set-up costs are extremely low compared to hard tooling.

- Initial quantities of newly designed parts can be produced on short notice – sometimes within days after the design is conceived.

- Revisions to part designs are similarly implemented quickly and economically.

Design Considerations

As you proceed with the design of your metal part, the following considerations will help you take full advantage of the Fotofab process.

- Material Selection

- Part Geometry Considerations

- Tolerances and metal thickness

- Selective Etching

- Tabs

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.

Why Use Fotofab for Metal Manufacturing?

Fotofab has been a pioneer in sheet metal component manufacturing for over 50 years. We work with industry leaders in Aerospace, Defense, Medical, Telecommunications, Automotive, and more to fabricate high-quality, precision parts on time and within budget.

Fotofab specializes in manufacturing precision metal parts while working with leaders in the medical, industrial, aerospace, and defense industries. Using the process of photochemical machining, also known as etching, Fotofab can achieve lower tooling costs and quicker lead times than traditional manufacturing methods