Reliable, Single-Use Metal Components for Medical Devices

A Medtech Makers Q&A

With environmental concerns growing, medtech manufacturers can consider metal for certain parts while remaining cost conscious.

By Sean Fenske, Editor-in-Chief

When someone thinks of single-use medical devices, the first material that typically comes to mind is plastic. Environmental impact, however, has become a greater factor in the sourcing of components for disposable healthcare products. As a result, medtech manufacturers are seeking alternative ideas with sustainability in mind.

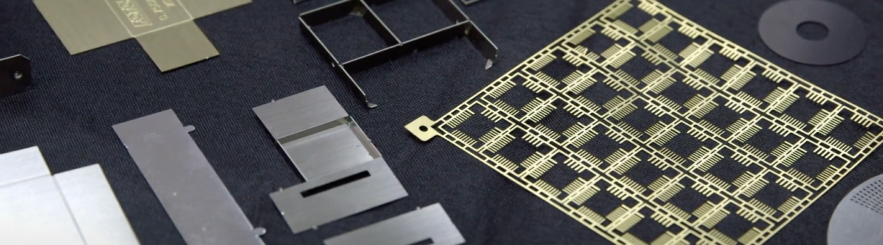

One such option is the use of metal parts instead of plastic. While the immediate thought with metal is strength and durability, cost also often comes to mind. Fortunately, there are metal fabrication processes that leverage the strength of the material to make components that require less volume of metal as compared to plastic, thus positively impacting the expense.

To offer more insight on how metal can be used in place of plastic for certain single-use medical device components, Jon Mills, business development manager at Fotofab LLC, addressed a number of questions in the following Q&A. He covers inquiries around expense of metal, design considerations, working with service partners, and more.