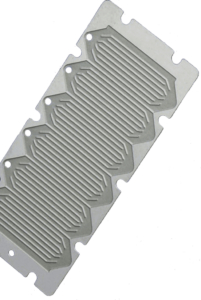

Photochemical Etched Fuel Cell Components

Fuel cells produce clean and efficient electricity using the chemical energy of hydrogen or another fuel source for a variety of transportation and power applications. They operate similarly to batteries, but they do not run down or need charging and continue to produce electricity if fuel is supplied. Some of the benefits that fuel cells have over combustion-based technologies include:

- Operate at higher efficiencies

- Convert the chemical energy in the fuel to electrical energy with efficiencies up to 60%

- Lower emissions

- Emit only water with no carbon dioxide emission or air pollutants that create smog and/or cause health problems

- Quiet operation

- Fewer moving parts

Fuel Cell Components

Fuel cells are composed of several components including anodes, cathodes, fuel cell stacks, bipolar plates, and gaskets; all of which are created by different manufacturing techniques.

Fotofab produces fuel cell plates, heat exchangers, and microfluidic control components from your choice of standard or exotic sheet metal. Our photochemical etching process manufactures burr- and stress-free plates with the internal intricacies needed for the overall fuel cell block, without adding to the cost as production quantities increase. We offer a standard lead time of 3-4 business days on etching and delivery depending on additional requested features.

With our value-added services, we are also capable of diffusion bonding the plates together to form the full fuel cell stack. Contact us today to see how we can help you turn hydrogen into electricity.

Typical Fuel Cell Applications

As energy-efficient trends continue to rise, fuel cells are becoming popular in a variety of applications including:

- Propulsion or auxiliary power for transportation in:

- Cars, Busses, and Trucks

- Trains

- Ships and Submarines

- Backup power for stationary applications including:

- Power for remote locations

- Stand-alone power plants for towns and cities

- Distributed generation for buildings

- Co-generation (in which excess thermal energy from electricity generation is used for heat)

Metals for Fuel Cells

There are a variety of materials used to manufacture the plates within a fuel stack. Metal materials are more robust, especially for automotive applications. Typical metals used for fuel cell stacks include:

Fotofab Advantages

Fotofab provides a wide range of high-precision metal fabricating services to produce components with simple to complex geometries. While our core competency has not changed over time, the technology of our production tools continues to evolve. We continue to seek opportunities for our customers to benefit from our unrivaled experience while producing parts with state-of-the-art production methodologies and uncompromising quality standards.

Benefits of Etched Fuel Cell Components

A Cost-Effective Alternative for Mass Producing Fuel Cell Stacks

Current manufacturing processes for fuel cell stacks and fuel plates can be slow, expensive, and labor intensive with low automation levels. Fotofab proposes a different solution for fuel call plates called photochemical machining or etching. The fabrication process has been around for over 50 years and is quicker, more cost-efficient, and more scalable.

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More