This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

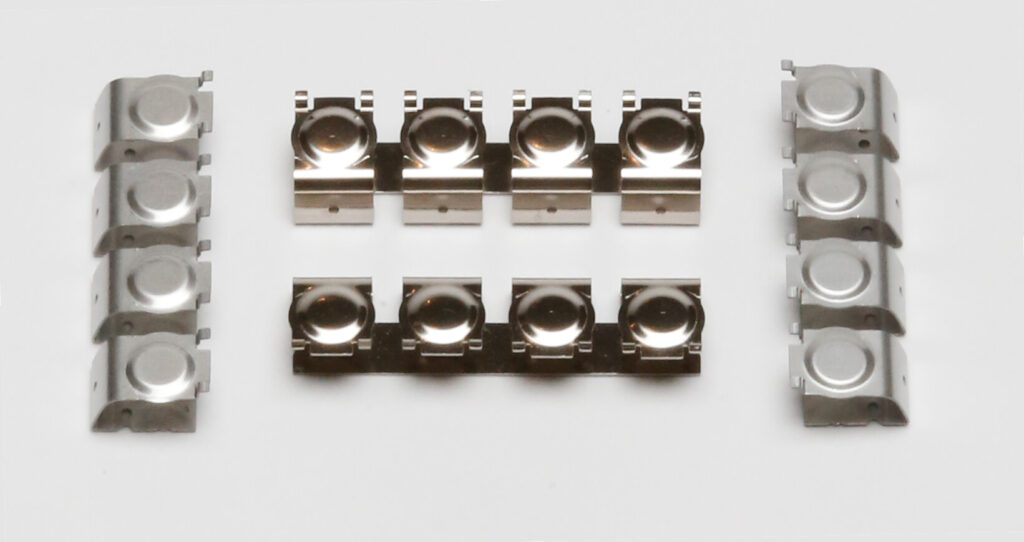

Precision Metal Plating for Etched Metal Parts

Industrial plating is the process of depositing a thin coating layer onto a metal substrate’s surface. The two major plating processes are electrolytic and electroless plating.

Electrolytic plating uses electricity to coat the base metal with a plating material.

Electroless plating uses a chemical reaction to deposit the plating material onto a metal substrate’s surface.

Plating metal parts can improve performance in a variety of ways including:

- Greater corrosion resistance

- Increased surface thickness

- Improved strength and durability

- Enhanced appearance

- Increased solderability

- Upgraded electrical conductivity

- Bolstered electrical resistance

- Greater wear resistance

With decades of experience, Fotofab can help identify the best plating process to achieve your specified goal. We work with you to develop a customized plan that minimizes operating costs and surpasses production timelines.

Plating Options for Etched Metal Parts

Our plating capabilities include standard types like Tin, Tin-Lead, Copper, and Nickel or precious metals like Gold, Silver, Platinum, Palladium, and Rhodium. We also are able to offer full or selective plating for your etched parts.

*Please note that plating services are only available on parts etched by Fotofab.

Standard Metal Plating

- Bright Tin (Mil-T-10727, Type I)

- Dull Electro Tin

- 60/40 Tin/Lead

- 63/37 (Eutectic) Tin/Lead

- 90/10 Tin/Lead

- Copper

- Electroless Nickel (Mil-C26074)

- Electrolytic Nickel (Mil-QQN-290)

Precious (noble) Metal Plating

- Hard Gold (Mil-G45204 Types I & II, Grades B & C)

- Soft Gold (Mil-G45204 Type III, Grade A)

- Matte finish Silver (Type I)

- Bright finish Silver (Type III)

- Platinum

- Palladium

Tin Plating

Used for excellent solderability and corrosion resistance

Nickel Plating

Generally used to improve corrosion and wear resistance of the underlying base metal. Nickel plating is magnetic and can have an appearance similar to Stainless Steel in color or an almost white, dull-grey color. Specify thicknesses ranging from 100u” up to 600u”.

- Electroless Nickel (Mil-C-26074) – good on flat or gently formed parts

- Electroplated Nickel (QQ-N-290)

*Both types of nickel plating are not recommended on parts with sharp, formed features as the brittle plating will crack when the part is formed.

Gold Plating

Generally used in parts where electrical conductivity and high corrosion resistance are required. If all you need is a gold flash, only 3-5 millionths of an inch of Type I, grade B is needed. Specify thickness from 10u” up to 100u”.

- Mil-G-45204

- Hard Gold (Types I & II, grades B & C)

- Soft Gold (Type III, grade A) – best used for wire bonding

Silver Plating

Has good corrosion resistance, depending on the base metal. Sometimes used where high electrical conductivity and excellent solderability (but decreases with age) are required. Specify thicknesses from 100u” up to 1000u”.

- QQ-S-365

- Matte finish Silver (Type I)

- Bright finish Silver (Type III)

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.