Metal Part Prototyping: Methods, Materials & Benefits

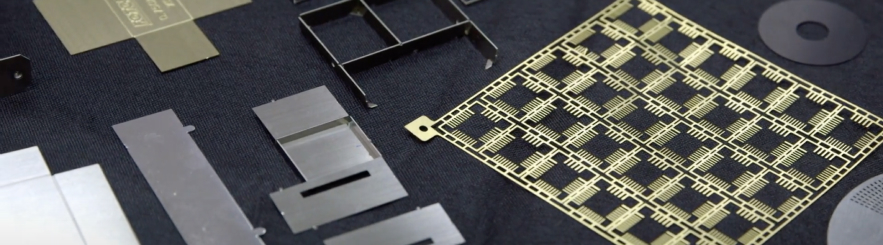

A critical phase in the product development cycle, metal prototyping enables engineers and designers to test, refine, and perfect their concepts before large-scale production. With the right prototyping process and materials, companies can use functional prototypes to identify potential issues, validate performance, and accelerate time-to-market.

With precision and speed paramount in this stage, your choice of prototyping method and material is critical.

Fotofab is an industry leader in rapid prototyping of thin metal components, with a proven track record for high accuracy, quick delivery, and an ability to work with highly precise tolerances. We work with industry leaders in Aerospace, Defense, Medical Devices and Implantables, Industrial, and Electronics to fabricate high-quality, precision parts on time and within budget.

In this article, we explore the popular methods for metal part prototyping, the advantages of working with a variety of metals, and the benefits of choosing Fotofab as your rapid prototyping partner.

What is Metal Part Prototyping?

Metal part prototyping involves creating small-volume models or metal prototypes to test their design, performance, and feasibility, before mass production.

There are several methods used for metal prototyping, including chemical etching, stamping, sheet metal fabrication, and wire EDM. Additional techniques such as 3D printing, CNC machining, laser cutting, direct metal laser sintering, and additive manufacturing have also become popular as digital technology continues to reshape the industry.

Fotofab specializes in producing your parts by whatever means necessary – chemical etching, stamping, forming, metal fabrication, and wire EDM, to name a few. Providing superior accuracy, fast turnaround times, and the ability to meet the tightest tolerances, we’ve quickly become the go-to partner for companies that need reliable and cost-effective prototyping solutions.

Methods for Metal Part Prototyping

Chemical Etching

Chemical etching, also known as photochemical etching, is one of the most precise and versatile methods for thin metal prototyping.

This method is ideal for producing complex geometries without introducing stress or distortion to the material, which is particularly beneficial for industries like aerospace and medical devices.

Fast, efficient, and cost-effective, the chemical etching process produces precision metal parts more precisely and with tighter tolerances than metal stamping, laser cutting, CNC machining, and wire EDM.

Fotofab is your trusted partner for precision chemical etching, offering unparalleled expertise in creating intricate parts with tight tolerances. Our process features a trio of fundamental improvements over other manufacturers, delivering reduced costs, faster speeds, and higher precision parts.

Metal Fabrication

Metal stamping and other metal forming operations are typically used for high-volume production runs but can also serve as a prototyping method when paired with other techniques. While producing and setting up tools can be time-consuming and expensive, Fotofab combines processes such as forming, punching, and bonding with photochemical etching to offer a more versatile approach.

This hybrid method accommodates different production scales and timelines, providing clients with a flexible and efficient solution for metal part prototyping. By incorporating both methods, the Fotofab team delivers high-quality prototypes with the speed and accuracy clients expect, regardless of the project size.

Wire EDM (Electrical Discharge Machining)

Wire EDM is a highly precise method used to cut intricate designs from metal using electrical discharges. This technique is ideal for prototypes that require extreme precision and tight tolerances. Although wire EDM is not as cost-efficient for large-scale production as chemical etching, it remains an excellent choice for specialized projects, particularly when working with thicker metal materials or small batch sizes.

Fotofab utilizes Wire EDM services both in the process of producing our hard tools for forming and stamping operations and in conjunction with photo-etching to produce an individual feature that cannot be produced by etching alone.

Fotofab’s Expertise and Variety of Metals

The material you choose in rapid prototyping is a crucial decision directly affecting the performance, durability, and suitability of the final product. Different metal components have unique properties such as strength, conductivity, corrosion resistance, and flexibility, which must align with the specific requirements of the prototype.

Selecting the right material ensures that the prototype accurately reflects the performance characteristics needed for the intended application, whether it’s for aerospace, medical devices, or electronics.

One key advantage of working with Fotofab is our ability to work with a wide range of metals. From stainless steel and copper to aluminum, titanium, and more, we offer flexibility in material selection to meet the specific requirements of each project.

This extensive range of metal material options enables us to provide tailored sheet metal prototyping solutions for various critical industries, from medical devices requiring biocompatible metals to electronics that need conductive materials.Fotofab’s experience extends beyond rapid metal prototype development – we also offer full-scale production parts. This means clients can transition rapidly and seamlessly from prototyping to mass production, knowing they’ll receive the same level of precision and quality throughout the process.

Benefits of Rapid Metal Prototyping with Fotofab

Faster Turnaround

In product development, time is often of the essence. Fotofab’s rapid prototyping services are designed to deliver prototypes in as little as 1-2 days, significantly reducing product development cycles. This quick turnaround time allows companies to test and refine their designs more efficiently, bringing products to market faster.

Superior Accuracy

Fotofab is known for its ability to work with metal components and sheet metal parts with micron level tolerances, ensuring that prototypes are manufactured with the highest level of precision. This level of accuracy is essential for industries where even the smallest deviations can impact performance, such as in aerospace or medical applications.

Cost-Effective Solutions

Compared to traditional machining methods, chemical etching and other rapid prototyping techniques offered by Fotofab are far more cost-effective, especially for complex parts. The absence of expensive hard tooling and the ability to quickly modify designs make these methods ideal for creating accurate, functional prototypes without breaking the budget while meeting project goals.

Flexibility in Design Changes

Design modifications are often necessary during the prototyping phase. Fotofab’s digital manufacturing process allows for easy adjustments without significant delays or additional costs. This flexibility saves time and resources, making the prototyping process more efficient and responsive to evolving project needs.

Masters of the Metal Prototype

Metal part prototyping is an essential step in developing high-quality, functional products. With speed and precision critical aspects of the prototyping process, you need to work with a prototyping partner with experience and expertise in a range of methods and materials.

When it comes to making metal prototypes, Fotofab is the best in the business. With over 50 years of experience delivering metal fabrications to industry leaders, our commitment to precision, quick turnaround times, and cost-effective solutions ensures that our clients receive prototypes that not only meet but exceed their expectations.

We’re experts in methods like chemical etching, stamping, and wire EDM, and we boast decades of experience working with a variety of metals. Whether you need a fast-turn prototype or a full-scale production run, Fotofab is your go-to partner for metal part prototyping.

Contact us today or request a quote for your next prototyping project.