This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Services

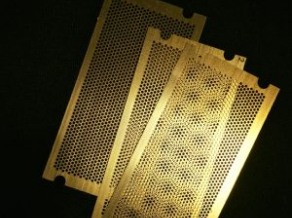

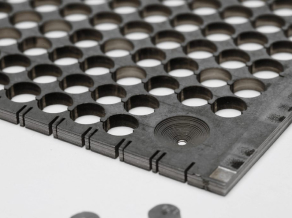

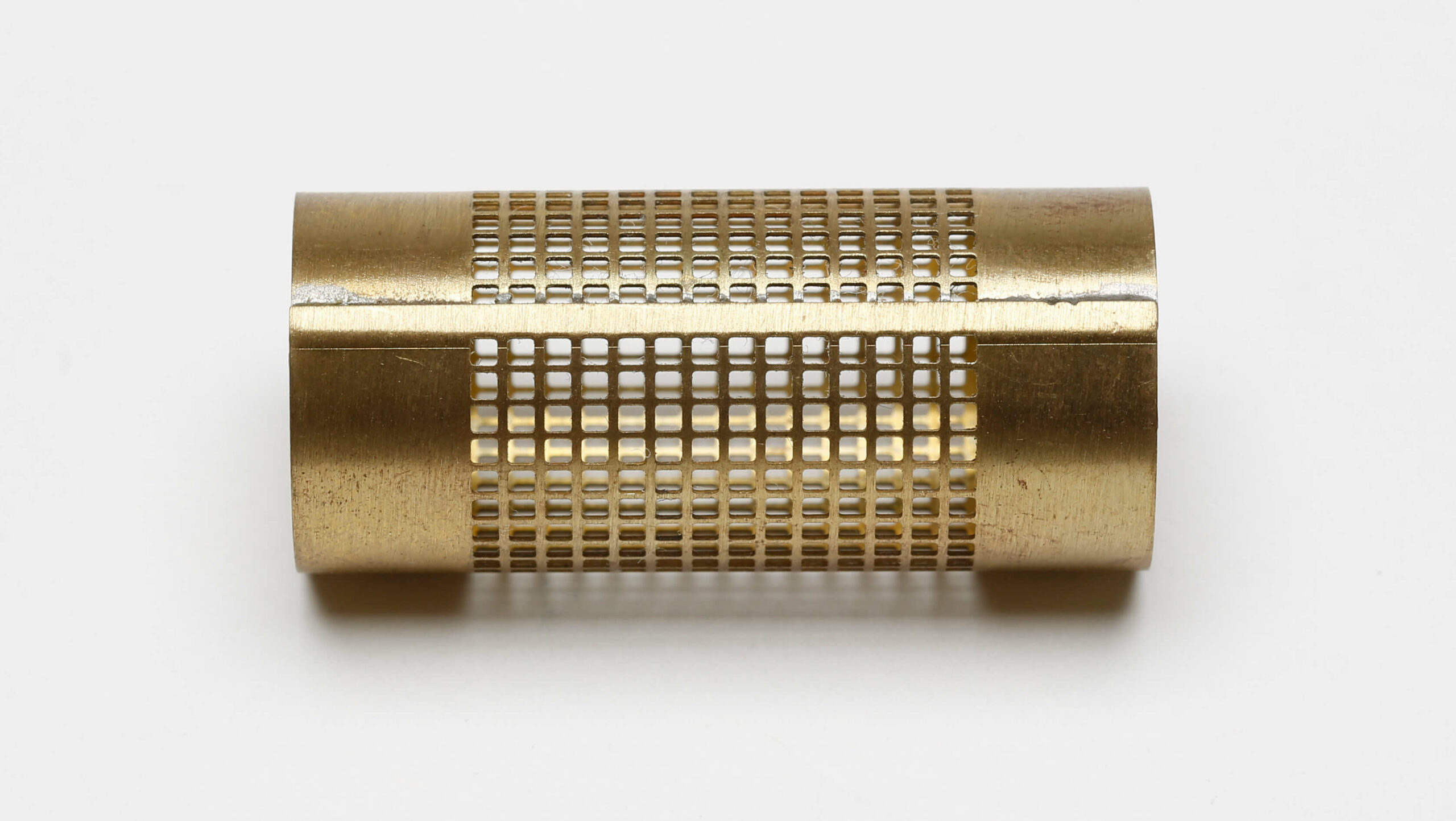

Fotofab is a full-service provider of high-quality thin metal parts. We offer an array of value-added and metal finishing options to bring you closer to the production finish line.

Value-Added Services

While photochemical machining is our core business, we can use our extensive production resources to give you a ready-to-use component, no matter what your requirement. Our metal component production services include:

- Manufacturing Value-Added Services

- Finishing Value-Added Services

Available Metals

Explore Metals We Chemically Etch

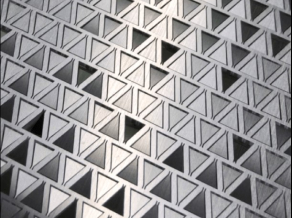

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals and alloys.

Fotofab is committed to quality.

Why Use Fotofab for Metal Manufacturing?

Fotofab has been a pioneer in sheet metal component manufacturing for over 50 years. We work with industry leaders in Aerospace, Defense, Medical, Telecommunications, Automotive, and more to fabricate high-quality, precision parts on time and within budget.

Fotofab specializes in manufacturing precision metal parts while working with leaders in the medical, industrial, aerospace, and defense industries. Using the process of photochemical machining, also known as etching, Fotofab can achieve lower tooling costs and quicker lead times than traditional manufacturing methods