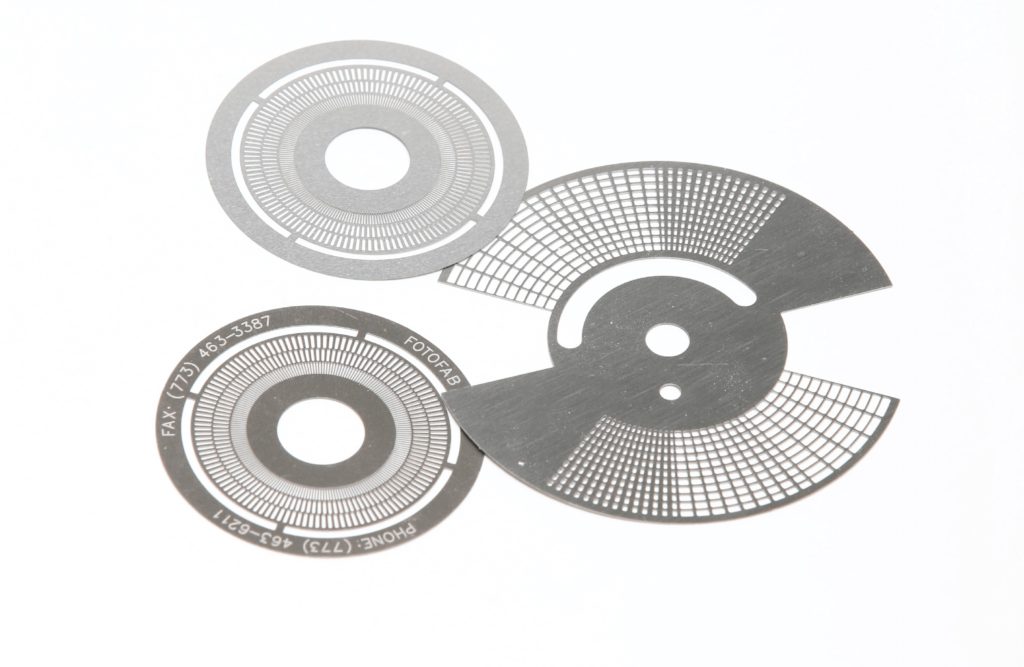

Optical Encoders

Encoders are pieces of optically opaque material filled with regularly shaped transparent openings or holes. Shaft encoders work in conjunction with a light source and photodetector to determine the position and/or speed of a moving object.

Applications of Optical Encoders

Looking to know how fast a motor is spinning? Put an optical encoder wheel with regularly spaced holes in it on one end of the motor shaft with a light on one side of it and a photodetector on the other.

Every time one of the spinning holes passes in front of the photodetector, the detector will register a pulse. If you know how many holes your rotary encoder has, you can calculate the speed of the motor by counting the pulses of light over time.

Other Factors

Rotary encoders are also used in positioning tables in much the same way, those encoders are long straight strips of metal with many of the same shaped holes arranged parallel to each other in a column.

There are no standards in the optical rotary encoder world, every application is different. Fotofab’s rotary encoder manufacturing process is very well suited to making a large number of very small holes in sheet metal simultaneously.

Because we etch our parts chemically using a photolithographic process it costs the same to produce one hole as it does to fill an entire sheet of metal with holes. We are also able to produce shaft encoders with much finer features and hold much tighter tolerances than other manufacturing methods for rotary encoders.

Available Metals

Explore Metals We Chemically Etch

Here at Fotofab, we provide photochemical machining (chemical etching, acid etching) services for a wide range of metals.

Fotofab is committed to quality.

Value Added Services for Chemically Etched Parts

Fotofab offers an array of value-added and finishing options to guarantee your project gets closer to the production finish line. While chemical etching is our core capability, we have an extensive list of resources to give you a ready-to-use component, no matter what your requirements, including:

- Forming

- Plating

- Passivation

- Diffusion Bonding

- Electropolishing

- Custom Packaging

- Laser Cutting & More